Table of Contents

1. General

General

It can be challenging to keep track of your hundreds or even thousands of facilities submitting their impact data each year. The Higg Adoption Tool enables real-time monitoring of your value chain partners’ progress towards the completion of the Higg Facility Modules (Facility Foundations, FEM, & FSLM) and the Higg Brand & Retail Modules (BRM Foundations & BRM).

As you manage facilities throughout this process, the Adoption Tool provides visibility into module completion, verification status, Higg account data, and share requests. As the single place for administration, communication, and tracking, the Adoption Tool ensures a smooth reporting period both for your company and your value chain partners.

What does adoption mean?

Higg adoption refers to the use of Higg tools. Adopting the Higg Facility Tools (Foundations, FEM, FSLM) requires your manufacturing partners to accept use of the Higg facility modules by completing the self-assessments and sharing the results. Adopting the Higg Brand and Retail Tools (BRM Foundations, BRM) requires your brand partners to accept use of the Higg Brand modules by completing the self-assessments and sharing the results.

What is a cadence?

A Higg cadence is a Higg module reporting period. Within the Higg Adoption Tool, a cadence is also a grouping mechanism defined by both Higg module type and time, that enables segmented tracking of Higg module completion across your value chain partners. For more information, refer to the Cadence Details and Management guidance.

Modules and Statuses

- No Module – No module has been purchased

- Module Acquire or NS – Module has been purchased, but has not been started

- ASI – In Progress

- ASC – Self Assessment Completed

- Verification Purchased – Self Assessment Completed & purchased verification

- VRP – Verification In Progress

- VRC – Verification Complete

- VRD – Verification Disputed

- VRF – Verification Finalized

- VRE – Verification Edit (if anything needs editing, a facility can apply for VRE)

- VRQ – Verification Quality Check

- VRI – Verification Invalidated (may occur if the facility disputes the verification and the VOO agrees with them)

- ASD – Assessment Deleted

The “No Account” status shows any facilities you have tried to add that did not have a Higg account. You can manage these additions during the account upload process. This status includes deleted modules, so sometimes you will see a negative “No Account” number.

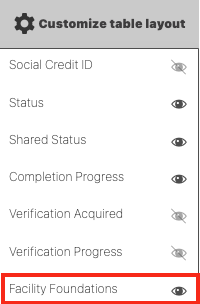

Navigate to the Cadence Details page of your FEM 2021 cadence. Scroll down to view the table grid of cadence member accounts. Click “Customize table layout” and make the Facility Foundations field visible. Once visible in your table, you will see Yes/No values under that column for each facility.

Cadence Setup and Management

All users will see a set of default cadences on their Adoption Tool dashboard, one per module type. These default cadences align with Cascale’s reporting period requirements, but the cadence names and dates are editable. For example, the default cadences for Higg FEM will be named “Default Cadence (FEM YYYY) with a default cadence end date of April 30 (reflecting Cascale’s self-assessment posting deadline). Once you add an account to a cadence, the account will receive an automatic share request from your account once they acquire the module. You will also immediately be able to view the Higg module completion status for that facility.

The April 30th deadline is something that had been evaluated and discussed at great length at Cascale through the Facilities Advisory Council. It is not a Higg Co requirement, but it was set by Cascale. The purpose of this is to align industry requirements around a common deadline. Over the last couple years, many members had implemented deadlines that were earlier than April (some as early as end of Feb, many in March) and the April deadline was an industry wide effort to come up with a compromise so that facilities weren’t facing different deadlines for publishing their FEM scores. Our experience is that facilities are easily able to post by this deadline. Many of the facilities who have used Higg in the past have used our “rollover” feature to copy over last year’s information and only update the new information. Those who do use this feature find it is very quick to update their modules.

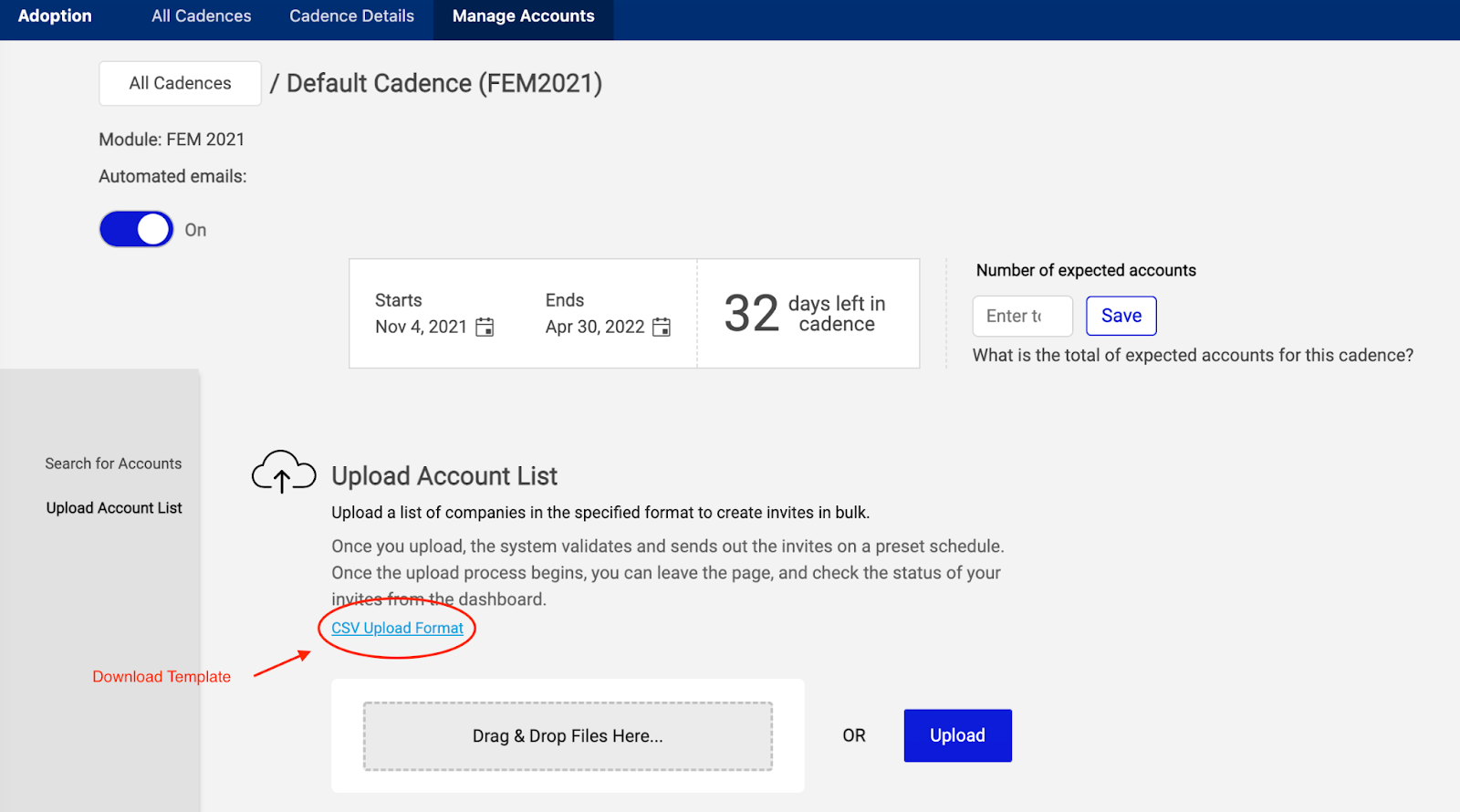

A CSV (comma delimited) file is the only file type that is accepted. The CSV template is available to download from the Upload Account List page in the Adoption Tool. You may find more information in the Upload Account List section of the guidance.

Advanced and Custom service accounts should refer to the Higg Customer Success team.

Yes. If you’re using the bulk import method, you can include the company name in your CSV import file. When you upload the file, the system performs a wildcard substring search using the company names provided in the file, to look for potential account matches.

You may also use the individual Search Accounts feature, by typing in the company name, partial company name, or Higg/Account ID in the search box, then selecting an account from the search results, and adding it to cadence from there.

You may find more information in the Add Accounts to Cadence section.

From your adoption dashboard, select a cadence by clicking on the cadence. This will take you to the Cadence Details page for the selected cadence. Once there, you will see a button labeled “Add Companies”. Once you click it, you will be taken to the page where you can select to either add accounts in bulk or search for individual accounts to add.

You may find more information in the Add Accounts to Cadence section.

Yes, you can immediately see the module completion and share status (i.e. Module Acquired, ASC, VRF, etc.) for each account that you’ve added to a cadence. But module data (responses) cannot be viewed until the account accepts your module share request AND posts the module. When an account is added to a cadence, they are notified and sent a request to share their module with your account.

From the Cadence Details page, scroll down to the table labeled Companies in Cadence. Search for the account you wish to remove, and once you find it, check the box to the left of the account. A blue bar will appear with actions, and you can select remove.

You may find more information in the Remove or Move Accounts section.

On the bottom of each Cadence Details page, there is a table that displays a list of accounts in the cadence. Search for the account you wish to move using either Higg ID or Account Name. Once you find it, check the box to the left of the account and click the blue Actions button. From the Actions dropdown, select Move to another cadence and click Apply. Follow the prompts to confirm the action.

You may find more information in the Move to Another Cadence section.

No, you will have to update that separately. If you remove an account from an adoption cadence and the account has not yet accepted your share request, you can go to your modules pages and cancel the share request (under Modules Requested). If the account has already accepted your module share request, you cannot remove it from your page.

Additional Features & Services

Please find more information on Higg Service Plans here.

Contact Higg to schedule a demo and to receive pricing details.