Higg FEM How to Higg Guide 2024

Table of Contents

General Introduction

There is a finite amount of water on Earth. The increase in global demand for water not only creates a risk for your business but creates a risk for your community and planet on a broader scale. The operational, environmental, and financial impacts of water use are key issues for facility operations. Driving efficient water use and reductions throughout facility operations is an important area of focus for all factories.

In general, the Higg FEM Water section encourages you to:

- Identify and understand all water sources and uses at the facility.

- Understand what operations and processes at your facility use the most water.

- Track and report the quantity of water consumption at your facility.

- Evaluate, plan for, and adopt solutions to reduce water use through better manufacturing practices and water reuse/recycling.

- Implement leading practices to reduce water use at your facility.

- Contribute to sustainable water management and water stewardship activities in your community.

Additional details on the intent and criteria for each Higg FEM Water question is provided in the guidance below along with useful technical guidance and resources to support your facility in the management and reduction of water usage.

Water Use at Your Facility

In the Higg FEM, water use is categorized as either used for production or domestic purposes as defined below:

- Water used for Production: Water used in manufacturing processes or operations used to make goods (e.g., dyeing or rinse water, steam generation, water used in mixtures applied to the product, cleaning of equipment components or tools that contact the product during the manufacturing process, etc.)

- Water used for Domestic Purposes: Water used for washrooms, sanitation, food preparation, landscape irrigation, non-contact cooling etc.

The Higg FEM requires facilities to select the sources of water used at their facility. The FEM includes a list of predefined sources that can be selected. The table below provides a description of the available water source options in the FEM. These are categorized blue and grey water sources.

| Water Source | Description |

| Blue Water Sources Blue water is fresh surface and groundwater, in other words, the water in freshwater lakes, rivers and aquifers | |

| Surface Water | Water that is naturally occurring on the Earth’s surface (ice sheets, ice caps, glaciers, icebergs, ponds, lakes, rivers / streams, wetlands, bogs, etc.) Surface water has a low concentration of dissolved solids, is of an acceptable quality, and/or requires minimal treatment to be used for domestic, municipal, or agricultural applications. |

| Groundwater | Water in soil beneath the soil surface, usually under conditions where the pressure in the water is greater than the atmospheric pressure, and the soil voids are substantially filled with the water. Non-renewable groundwater is generally located at deeper depths and cannot be replenished easily or is replenished over very long periods of time. They are sometimes referred to as “fossil” groundwater sources. |

| Municipal Blue Water | Water provided by a municipality or other public provider that is generated by blue water. |

| Municipal Water (Origin Unknown) | Water provided by a municipality or other public provider with unknown origin (e.g., blue, or grey water) |

| Brackish surface water/seawater | Water in which the concentration of salts is relatively high (over 10,000 mg/l). For comparison, seawater has a typical concentration of salts above 35,000 mg/l. Brackish water is saltier than fresh water, but not as salty as seawater. It may result from mixing of seawater with freshwater, as in estuaries, but also certain human activities can produce brackish water. Brackish water is hostile to the growth of most terrestrial plant species. |

| Condensate from External Steam Source | Water that is generated from the condensate of steam sources that are not located at the facility. |

| Rainwater | Water in the form of precipitation (e.g., rain, snow) that is harvested within the facility either from the roof or other surfaces and stored for use. |

| Grey Water Sources Grey water is water that has been polluted by human activity (e.g., industrial, or domestic sources) | |

| Municipal Grey Water | Water provided by a municipality or other public provider that is generated by grey water. |

| Recycled Water | Wastewater that has been treated using physical, chemical, and/or any additional treatment processes to meet a quality which allows the water to be used again in a process or for domestic purposes. For example, wastewater that has gone through a membrane filtration process and used back in the industrial operation is considered recycled water. This does not include water cycled in operations such as cooling towers and non-contact heat exchange operations. |

| Reuse Water | Wastewater discharged from one process that is used directly in another process without treatment. This does not include water cycled in operations such as cooling towers and non-contact heat exchange operations. |

| Treated Wastewater from External Source | Wastewater that has been discharged and treated by an external source (e.g., other manufacturing facility) using physical, chemical, and/or any additional treatment processes to meet a quality which allows the water to be used again in a process. |

| Untreated Wastewater from External Sources (treated internally) | Wastewater that has been discharged by an external source (e.g., other manufacturing facility) and treated at your facility using physical, chemical, and/or any additional treatment processes to meet a quality which allows the water to be used again in a process. |

Water Data Quality

Accurately tracking and reporting water use data overtime provides facilities and stakeholders with detailed insight into opportunities for improvement. If data is not accurate, this limits the ability to understand a facility’s water use footprint and identify the specific actions that will help reduce environmental impacts and drive efficiencies. When establishing a water tracking and reporting program, the following principles should be applied:- Completeness – The tracking and reporting program should include all relevant sources (as listed in the FEM). Sources should not be excluded from data tracking and reporting should be based on materiality (e.g., small quantity exceptions).

- Accuracy – Ensure that the data input into the water tracking program is accurate and is derived from credible sources (e.g., calibrated meters, established scientific measurement principles or engineering estimates, etc.)

- Consistency – Use consistent methodologies to track water data that allows for comparisons of water use over time. If there are any changes in the tracking methods, water sources, or other operations that impact water use data, this should be documented.

- Transparency – All data sources (e.g., water bills, meter readings, etc.), assumptions used (e.g., estimation techniques), and calculation methodologies should be disclosed in data inventories and be readily verifiable via documented records and supporting evidence.

- Data Quality Management – Quality assurance activities (internal or external data quality checks) should be defined and performed on water data as well as the processes used to collect and track data to ensure reported data is accurate.

Applicability Questions

To determine which questions you will need to complete in the Water section, you will need to complete the applicability questions listed below.

Based on the response to the applicability questions, facilities will be classified as a high or low water user, and a facility in an area of high or low water risk as follows:

- Facilities with low water use (defined as using less than 35m3 per operating day)

- Facilities with high water use (defined as using equal to or greater than 35m3 per operating day)

- Facility located in an area of low water risk (as defined by the WRI Aqueduct Tool or the WWF Water Risk Filter).

- Facility located in an area of high water risk (as defined by the WRI Aqueduct Tool or the WWF Water Risk Filter).

Facilities that are classified as either high water users or located in an area of high water risk (or both) will be asked to complete all FEM questions in the water section. Facilities classified as low water users that are located in areas of low water risk will only answer Level 1 questions.

1. How many days did your facility operate during this reporting year?

- List the number of days the facility operated in the reporting year.

- Note: Refer to the Site Information & Permits Section of the Higg FEM guidance on how to determine the number of operating days.

2. Select the tool used to assess your facility’s water risk.

- WWF

- WRI

Facilities will be asked to evaluate their water risk using both the WRI Aqueduct Tool and the WWF Water Risk Filter.

Notes:

- Facilities must report their water risk based on the highest water risk ratings from the two tools (e.g., if the WRI tool shows low risk and the WWF tool shows high risk, the high risk must be reported).

- Facilities should capture screenshots and/or downloads of the risk assessment outcome and upload as evidence to show that the risk assessment was done within the FEM reporting year.

The WRI Aqueduct Tool and the WWF Water Risk Filter are simple and similar tools to assess water scarcity risks.

When using the WRI Aqueduct Tool go to the home page and select explore global water risk maps and select Enter Address at the bottom of the screen to search using your facility address. Facility should select the default Overall Water Risk weighing scheme.

When using WWF Water Risk Filter, click on the maps feature under the Water Risk menu option and search for your country and location. Look at the color-coding of the map to determine the Basin Physical risk for the area your facility is located . This link provides information on the data and methodology and scoring matrix used in the Risk Filter.

Note: “Low risk”, “Low to medium risk” and “Medium to high risk” are defined as “Low risk” in FEM. “High risk” and “Extremely/Very high risk” are defined as “High risk” in FEM.

3. Is your facility location rated as high/very high for overall water risk using this tool?

- Yes

- No

4. Is your facility using water for production use?

- Yes

- No

5. Is your facility able to separately report water consumption by each facility type?

- Yes

- No

Answer Yes If: Your facility tracks water consumption separately for the different facility types selected in the Site Info Section of the FEM.

Note: This applicability question will only apply to facilities that have selected “Finished Product Assembler” AND “Finished Product Processing” as the only two facility types in the Site Info Section of the FEM.

Water – Level 1

- Water Source Category

- Blue Water

- Surface Water

- Groundwater

- Municipal Blue Water

- Municipal Water (Origin Unknown)

- Brackish surface water/seawater

- Condensate from External Steam Source

- Rainwater

- Grey Water

- Municipal Grey Water

- Recycled Water

- Reuse Water

- Treated Wastewater from External Source

- Untreated Wastewater from External Sources (treated internally)

- Blue Water

Note: For information on the definitions of the above water sources, please refer to the Introduction Section of the water guidance.

After selection your water sources and based on your water question applicability responses, you will be asked the following series of questions to provide additional details on your water sources and consumption tracking:

Answer

- Yes

- No

Answer Yes If: Your facility tracks water use from one (1) or more of its water sources.

Note: If you answer No to this question, no further questions will be asked, and you will receive a score of zero (0) in the water section.

- Yes

- Partial Yes

- No

Answer Yes If: Your facility tracks water use from all water sources used.

Answer Partial Yes If: Your facility tracks water use from one (1) or more, but not all of its water sources.

Note: If you answer No to this question, this means that you do not track water use for any sources and the answer to the previous question should also be No. In this case, no further questions will be asked, and you will receive a score of zero (0) in the water section.

If you answer Yes or Partial Yes to the questions above, you will be asked the following sub question on water tracking.

3.1. Is your facility able to separate and report water consumption by facility type for tracked water sources directly from captured data without relying on estimation? (Ref ID – watsourcetrackoptmethod)

What is the intent of this question?

- The intent of this question is for facilities to indicate whether their reported water consumption split across different facility types is based on estimates or based on direct measurement of water sources at each applicable facility type.

- Answer Yes if : Your water consumption for all tracked water sources is based on data measured directly at each facility type

- Answer Partial Yes if : Your water consumption for only some tracked water sources is based on data measured directly at each facility type and other tracked water consumption is split using estimation.

- Answer No if: Your facility uses an estimation methodology to calculate the breakdown of water usage for all water sources across all facility types.

- Yes

- No

Answer Yes If: Your consumption tracking includes rejected water from onsite pre-treatment of incoming water.

Note: This question only applies to facilities that have indicated that pre-treatment of incoming water occurs onsite in the Site Info section of the FEM.

This question is not scored in the 2023 Higg FEM reporting year. Scoring may be applied in future reporting years.

If you answer Yes to this question, you will be asked the following sub questions:

- Please select the type/s of treatment.

- Does your facility measure the quantity of water rejected from the pre-treatment?

- What are the water sources that you send through pre-treatment?

- Please indicate the annual quantity (m3).

- What is the reject percentage (%)?

- What is the method of disposal of the rejected water?

- If Other, please describe.

- Please upload your facility’s freshwater pre-treatment process flow and hydraulic diagrams if you have one.

Answer

Answer

Answer

Answer

Answer

Answer

Answer

Answer

- Yes

- No

Answer Yes If: Your facility tracks water use tracks domestic and production water use separately.

Note: This question only applies to facilities that have indicated water is used for production in the applicability question on production water use.

If you answer Yes to this question, you will be asked to complete two (2) tables to provide details on your facility’s domestic and production water use for each applicable water source.

Note: If your facility selects multiple facility types in the facility profile structure section of the FEM (e.g., Finished Product Assembler and Material Production), a separate table for production water use will be displayed for each selected facility type.

If you answer No to this question, you will be asked to complete a single table to provide details on your facility’s total water use for each applicable water source.

The following question on your facility’s water use will be asked for each applicable water source:

- Does your facility use this water source for Domestic/Production Use?

- Does your facility track its water use from this source?

- What quantity of water was used from this source for Domestic/Production Use during this reporting year?

- Unit of Measure

- Which method was used to track this water source?

- What was the frequency of measurement?

- Provide any additional comments.

Suggested Uploads:

- Documentation that demonstrates the facility has identified water sources and is tracking water consumption for applicable water sources. (e.g., an inventory and/or tracking records for water sources, samples of water purchase invoices or metering records, etc.)

Note: Uploading of all utility bills and/or metering records is not required, however they should be available for review at the time of verification.

This question is not scored in the 2023 Higg FEM reporting year. Scoring may be applied in future reporting years.

What is the intent of these questions?

The intent of these questions is to help facilities understand the sources of the water they are using, and the quantity of water used from each source.

Technical Guidance

Identifying and measuring water use from all sources is the foundation of a water management program and the overall sustainability program for a company. Measurement of all water sources allows you to identify areas of significant water use, detect any abnormal consumption, and establish water use baselines and reduction targets. Additionally, tracking domestic and production water use separately can help facilities further identify specific areas for improvement and conservation efforts.

When establishing your water tracking and reporting program, start by doing the following:

- Mapping out business and operational processes to identify water sources, areas/processes that consume water.

- Establish procedures to collect and track water use data:

- Use utility bills to determine the quantity of purchased water.

- Determine methods to track water consumption from other applicable sources, such as rainwater, recycled water, etc.

- Install sub-meters to track the amount of water used on-site.

- If estimation techniques are used to determine water use, the calculation methodology should be clearly defined and be supported by verifiable data.

- Take inventory of how the site obtains water and gathers information on where the water comes from and who or what supplies the water.

- Record tracking data (e.g., daily, weekly, monthly consumption records) in a format that is easy to review [e.g., spreadsheet (e.g., Microsoft Excel) or similar data analytics program that allows export of data in a readable format (e.g., Excel, csv)] and maintain relevant supporting evidence for review during verification.

Reporting Water Use Data in Higg FEM:

Before reporting water use data in the FEM, data quality checks should be performed to ensure that the data AND the processes used to collect and record the data are effective at producing accurate data.

Do:

- Review source data (e.g., utility invoices, meter logs, etc) against aggregated totals to ensure it is accurate.

- Compare the current year with historical data. Any significant changes (e.g., an increase or decrease of over 10%) should be attributable to known changes. If not, further investigation may be warranted.

- Ensure the most recent and updated versions of data tracking spreadsheets are being used and that all automated calculations/formulas are correct.

- Ensure the proper units are reported and verify any unit conversions from source data to reported data.

- Review any assumption or estimation methodology/calculations to ensure accuracy.

Do Not:

- Report data that is not accurate (e.g., the data source is unknown or has not been verified).

- Report estimated data if it is not supported by verifiable and reasonably accurate estimation methodology and data (e.g., engineering calculations).

How This Will Be Verified:

When verifying a facility’s water sources, Verifiers must review all aspects of the facility’s water tracking program that could produce inaccuracies including:

- The initial data collection processes and data sources (e.g., invoices, on-site meters, metering logs, etc.); and

- The process and tools used to aggregate the data (e.g., spreadsheet calculations, unit conversions, etc.)

Full Points:

Full points will be awarded to facilities that track water use from all applicable water sources.

Documentation Required:

- Documentation that supports the reported water source and water use data which may include:

- List of all water sources used at the facility.

- Water consumption records (e.g., utility bills, metering records, etc)

- Note: Annual consumption records compiled in a spreadsheet (e.g., Excel) is ok if detailed consumption records are available for review.

- Water meter calibration records where applicable (e.g., as per manufacturer’s specifications)

- Documented estimation methodologies if applicable.

- Documentation that supports responses to the sub questions on water source. This may include:

- Water treatment/reject quantity tracking from pre-treatment processes.

- Records of tracking domestic and production water separately, if applicable.

Interview Questions to Ask:

- Staff responsible for managing water can explain the facility’s water tracking program (e.g., how water sources are identified, and water use quantities are tracked).

- Key staff should understand:

- The procedures in place for tracking water use.

- How data quality of the water use tracking program is maintained.

- Any estimation methodologies used to calculate annual water use.

Inspection – Things to Physically Look For:

- All water sources observed are properly identified and tracked.

- Appropriate equipment for water use measurement is present (e.g., meters) if applicable.

Partial Points:

- Partial Points will be awarded to facilities that fully track at least one (1), but not all water sources.

Answer

Note: This question only applies to facilities that use groundwater as indicated in the water applicability questions.

Answer Yes if: There are legally mandated groundwater abstraction restrictions in the facility’s country or jurisdiction of operation that apply to your facility (e.g., limits on the amount of water that can be extracted).

Answer Unknown if: You cannot confirm the presence or absence of legally mandated groundwater abstraction restrictions in the facility’s country and/or jurisdiction of operation that apply to your facility.

If you select Yes, you will be asked the following sub question(s):

- Please upload the relevant legal regulation.

- Please provide the following information.

- How much in m3/h is your facility allowed to abstract ground water? (m3/h)

- How much in m3/day is your facility allowed to abstract ground water? (m3/day)

- How much per unit of time is your facility allowed to abstract ground water? (m3/unit of time)

- Are you abstracting within the legal limit?

Suggested Uploads:

- Copies of the applicable laws or regulations that specify groundwater abstraction restrictions in your country or jurisdiction of operation (e.g., water resource management acts, water use permits, or groundwater protection regulations, etc).

- Copy of the facility’s groundwater abstraction permit showing the permissible extraction volume, restrictions, and any applicable monitoring or reporting requirements.

- Groundwater abstraction/consumption tracking records (e.g., metering logs).

What is the intent of the question?

The intent of this question is for facilities to ensure they understand and are complying with any applicable legal requirements related to groundwater abstraction.

Technical Guidance

Legally mandated groundwater abstraction restrictions are typically in place to prevent over-extraction, protect the environment, and maintain a balance between water supply and demand for various users, including the natural ecosystems and surrounding communities.

It is important that facilities understand any applicable legal requirements and/or restrictions related to groundwater abstraction and establish appropriate procedures and practices to ensure compliance. If your facility requires a permit or license for groundwater abstraction, facilities should review the permit and applicable regulations to ensure all requirements (e.g., permissible abstraction volumes, monitoring, and reporting requirements) are fully understood.

How This Will Be Verified:

Full Points:

Full points will be awarded if there are applicable legally mandated groundwater abstraction restrictions in the facility’s country or jurisdiction of operation that apply to your facility and the facility is in compliance with these requirements.

Note: If there are no applicable legally mandated groundwater abstraction restrictions in the facility’s country or jurisdiction of operation that apply to your facility. This question will be unscored and will not impact the overall Water section scoring.

Documentation Required:

- Documentation that demonstrates the facility is aware of and complying with any applicable legal requirements related to groundwater abstraction. This may include:

- Copies of the applicable laws or regulations that specify groundwater abstraction restrictions in your country or jurisdiction of operation (e.g., water resource management acts, water use permits, or groundwater protection regulations, etc).

- Copy of the facility’s groundwater abstraction permit showing the permissible extraction volume, restrictions, and any applicable monitoring or reporting requirements.

- Groundwater abstraction/consumption tracking records (e.g., metering logs).

Interview Questions to Ask:

- Staff responsible for water management and groundwater abstraction at the facility understand any applicable regulations and/or permitting requirements related to groundwater abstraction and can explain the facility’s procedures for monitoring groundwater use and ensuring compliance with applicable requirements.

Inspection – Things to Physically Look For:

- Observations on site indicate that the facility is operating its groundwater wells in compliance with any applicable requirements (e.g., all wells have applicable permits, when required, abstraction/consumption records do not exceed the permissible volume).

Partial Points: N/A

Answer

Answer

Answer

Answer

Answer

Answer Yes if: Your facility has a process in place to identify, prevent and monitor potential leaks that covers all components of your facility’s water supply network (i.e. all infrastructure components that distribute/transfer water from its source to points of use within your facility).

If you select Yes, you will be asked the following sub question(s):

- If yes, please describe how you monitor.

- Please upload documentation.

Suggested Uploads:

- Documentation that shows the facility’s process for inspecting and monitoring all water supply network components at your facility (e.g., preventative maintenance/inspection schedules or procedures, completed inspection checklists or maintenance records, etc.)

What is the intent of the question?

The intent of this question is to ensure that facilities have an established process in place to proactively identify and prevent leaks in the water supply network.

Technical Guidance

Leaks in the water supply network can lead to significant losses which can have both an environmental and financial impact. Preventative maintenance is maintenance that is regularly scheduled and performed on equipment to reduce the chance of water loss due to equipment/component failure and identify potential problems before they result in breakdowns or leaks. Regular inspections and maintenance should be planned and scheduled based on available information for each piece of equipment (e.g., manufacturer’s recommendations for inspection/maintenance, past breakdowns or leaks, operating conditions, etc.)

The water supply network in a facility consists of interconnected infrastructure components designed to collect, store, and distribute water throughout the facility. Key elements that should be covered in a facility’s inspection and maintenance program include:

- Water storage (e.g., tanks and reservoirs)

- Water distribution system (e.g., pipes, pumps, valves)

- Equipment/facilities that use water for production and domestic use.

It is also important to ensure responsible staff are properly trained on leak detection and response to ensure leaks are detected and fixed as soon as possible.

How This Will Be Verified:

Full Points:

Documentation Required:

- Inspection and/or maintenance plan that covers all water supply network components at the facility. This may include:

- Inspection and maintenance schedule or procedures

- Preventative maintenance procedures

- Completed inspection checklists.

- Service records or maintenance logs

Note: If the facility’s equipment is inspected and maintained by a third-party service provider, copies of relevant inspection and maintenance documentation such as those listed above should be made available for verification.

Interview Questions to Ask:

- Staff responsible for the maintenance and/or inspection of the facility’s water supply network understand and can explain the facility’s inspection and maintenance procedures.

Inspection – Things to Physically Look For:

- All water supply network components (e.g., tanks, pumps, piping) are in good working repair and observations indicate that regular inspection and maintenance is conducted as per the facility’s procedures.

Partial Points: N/A

Answer

Answer

Water Level 2

Higg FEM Level Progression

If your facility did not achieve Level 1 in this section, you will have the option to complete Level 2 and 3 questions and will be asked the following question:

Your facility has not achieved Level 1 within this section, the maximum score for this section will be limited to your answers in Level 1, You now have the option to answer Level 2 and Level 3 questions, would you prefer to proceed answering these additional questions?

If you Answer Yes: Level 2 and 3 questions will be available to answer in this section.

If you Answer No: Level 2 and 3 questions will not be available in this section.

Notes:

- If your facility did not achieve Level 1 in this section, answering Level 2 and 3 questions will not result in additional score beyond what you have already achieved in Level 1

- It is recommended that facilities consult with their business partners on whether they require responses to Level 2 and Level 3 questions, even though you have not achieved Level 1 in this specific section.

- Facilities are encouraged to complete Level 2 and Level 3 questions when possible as these can provide valuable insights on your facilities environmental performance and opportunities for improvement with the advanced Higg FEM aspects in Level 2 and 3

Answer Yes if: Your facility has set a baseline for one (1) or more water sources.

If you answer Yes to this question, you will be asked to complete a series of question and tables based on your facility’s water use applicability with the following questions to provide details on your baselines for each applicable water source (All applicable water sources will be pre-populated in the tables):

This question is not scored in the 2024 Higg FEM reporting year. Scoring may be applied in future reporting years.

- Note: This question only applies to facilities that use water in production and track production and domestic water use separately.

This question is not scored in the 2023 Higg FEM reporting year. Scoring may be applied in future reporting years.

- Have you set a baseline for this water source?

- Is this a normalized or absolute baseline?

- If normalized, are you setting separate baselines based on your facility type?

- Notes:

- This only question applies to facilities that use water in production.

- If your facility selected multiple facility types in the facility profile structure section of the FEM (e.g., Finished Product Assembler and Material Production), and you set baselines for each facility type, a separate table for baseline data will be displayed for each selected facility type.

- Notes:

Notes:

- Facilities that use water for production and do not separately track or set baselines for production and domestic water use will complete one (1) baseline table for combined production and domestic water use.

- Facilities that use water in production and separately track and have set baselines for production and domestic use separately will complete separate baseline tables for production and domestic water use.

For all water sources that have baselines, you will be asked to complete a table with the following questions based on whether the baseline is absolute or normalized:

| Absolute Baselines | Normalized Baselines |

| What is the baseline quantity for this source? | What is the baseline quantity for this source? |

| Unit of Measure | Unit of Measure |

| Enter baseline year | What is your normalized baseline based on? |

| How was your baseline calculated? | Enter baseline year. |

| Was the baseline verified? | How was your baseline calculated? |

| Provide any additional comments | Was the baseline verified? |

| Provide any additional comments |

Note: From FEM2024 onwards, in the above table, baseline data can be auto populated or manually entered in the following ways:

- New FEM Users: Required to manually input baseline.

- Existing FEM Users without a baseline: Facility can choose to:

- Enter the baseline manually OR

- Have the FEM auto populate a baseline based on the data from the previous year’s FEM.

- Existing FEM Users with an existing baseline: Baseline will auto populate based on the data from the previous year’s FEM.

Suggested Uploads:

- Documentation that supports how the baseline was established for each water source (e.g., water use tracking data and production data from the baseline year, supporting calculations or assumptions used to determine the baseline).

What is the intent of the question?

The intent of this question is for facilities to demonstrate that they have established baselines for water use at the facility so that future reduction efforts can be quantified.

Technical Guidance:

A “baseline” is a starting point or benchmark that a facility can use to compare changes over time and quantify any reduction efforts.

Baselines can be absolute or normalized. For example:

- Absolute: The total amount of water used for a period of time. (e.g., 1,500,000 of municipal water used in the reporting year)

- Normalized: The amount of water used while making a unit of product (e.g., 0.15 m3 per pair of shoes produced).

Note: It is recommended to use the ‘Normalized’ method to account for operational fluctuations. Normalized baselines provide more accurate and useful comparisons over time.

When establishing a baseline, be sure to do the following:

- Confirm the water source data is stable, and sufficient to be used to determine a baseline. In the Higg FEM, a baseline should generally comprise of a full calendar year’s data.

- Note: If your factory has undergone major structural or operational changes such as acquisition or changes in product type, in general, you should establish or reset a baseline after those changes have been completed.

- Determine if the baseline will be Absolute or Normalized (Normalized baselines are preferred)

- Verify the source data and normalizing metrics data is accurate.

- Water and production volume data from previous Higg FEM verifications, internal or external audits conducted by qualified personnel are acceptable sources of data verification.

- Apply the appropriate baseline metric (i.e., per year for absolute OR divide by the chosen normalizing metric 150,000 m3 per 1,000,000 pieces = 0.15m3/piece)

- Note: For water consumption that is not related to production, other normalizing metrics should be used where appropriate (e.g., water consumption per worker).

Note: If the baseline is used to evaluate performance against a target, the baseline should remain unchanged.

Reporting baseline data in Higg FEM:

Do:

- Review source data and raw normalizing metric data (utility invoices, meter logs, production quantity, etc.) against aggregated totals used to determine the baseline(s) to ensure they are accurate. (e.g., double check monthly water consumption records to ensure they match the annual consumption quantities used to calculate the baseline).

- Select the appropriate baseline type in the FEM – Absolute or Normalized.

- Ensure the proper units are reported and verify any unit conversions from source data to reported data.

- Enter the baseline year. This is the year the baseline data represents.

- Provide sufficient details on how the baseline was calculated (e.g., water consumption was normalized per meter of fabric produced).

- Only select Yes to the question “Was the baseline verified?” if the baseline data was fully verified in a previous Higg FEM verification, or by an internal or external audit conducted by qualified personnel.

Do Not:

- Report a baseline that is not accurate (e.g., the data source is unknown or has not been verified)

- Report a baseline that is based on insufficient data (e.g., not a full year’s data).

- Report an estimated baseline if it is not supported by verifiable and accurate estimation methodology and data (e.g., engineering calculations).

How This Will Be Verified:

When verifying a facility’s baselines, Verifiers must review:

- All source data (utility invoices, metering logs, production quantity) and aggregated data totals for the baseline year; and/or

- Records of baseline data verification where available (e.g., previous Higg Verification, data quality review, internal or external audits, etc.)

If any inconsistencies or errors are noted, the reported information must be corrected where possible and detailed comments should be included in the Verification Data field.

Full Points:

Full Points will be awarded if the facility has established baselines for all water applicable sources.

Documentation Required:

- Documentation that supports how the baseline was established for each water source. This may include:

- Water use tracking and production data from the baseline year (separated by production and domestic use, if applicable).

- Supporting calculations methodologies or assumptions used to determine the baseline.

- Supporting evidence to demonstrate how baseline data was validated (e.g., verified Higg FEM data for the baseline year, external or internal data validation process or report).

Interview Questions to Ask:

- Staff responsible for water management are able to describe how the baselines were determined including any normalizing metrics used or any assumption made in the calculation methodology.

- Relevant staff are able to describe the facility’s process to validate the accuracy of baseline data.

Inspection – Things to Physically Look For:

- The observed water management practices on-site are consistent with the facility’s reported methods for determining baselines (e.g., water sources used, water use tracking methods/equipment, etc.)

- Observations on-site do not indicate that there have been significant changes at the facility that could impact the appropriateness of the baseline (e.g., new production areas, changes to products, new buildings, etc.)

Partial Points:

- Partial points will be awarded if the facility has established baselines for one (1) or more, but not all applicable water sources.

- Have you set a baseline for this water source?

- Is this a normalized or absolute baseline?

- If normalized, are you setting separate baselines based on your facility type?

- Notes:

- This only question applies to facilities that use water in production.

- If your facility selected multiple facility types in the facility profile structure section of the FEM (e.g., Finished Product Assembler and Material Production), and you set baselines for each facility type, a separate table for baseline data will be displayed for each selected facility type.

- Notes:

Notes:

- Facilities that use water for production and do not separately track or set baselines for production and domestic water use will complete one (1) baseline table for combined production and domestic water use.

- Facilities that use water in production and separately track and have set baselines for production and domestic use separately will complete separate baseline tables for production and domestic water use.

For all water sources that have baselines, you will be asked to complete a table with the following questions based on whether the baseline is absolute or normalized:

| Absolute Baselines | Normalized Baselines |

| What is the baseline quantity for this source? | What is the baseline quantity for this source? |

| Unit of Measure | Unit of Measure |

| Enter baseline year | What is your normalized baseline based on? |

| How was your baseline calculated? | Enter baseline year. |

| Was the baseline verified? | How was your baseline calculated? |

| Provide any additional comments | Was the baseline verified? |

| Provide any additional comments |

Note: From FEM2024 onwards, in the above table, baseline data can be auto populated or manually entered in the following ways:

- New FEM Users: Required to manually input baseline.

- Existing FEM Users without a baseline: Facility can choose to:

- Enter the baseline manually OR

- Have the FEM auto populate a baseline based on the data from the previous year’s FEM.

- Existing FEM Users with an existing baseline: Baseline will auto populate based on the data from the previous year’s FEM.

Suggested Uploads:

- Documentation that supports how the baseline was established for each water source (e.g., water use tracking data and production data from the baseline year, supporting calculations or assumptions used to determine the baseline).

What is the intent of the question?

The intent of this question is for facilities to demonstrate that they have established baselines for water use at the facility so that future reduction efforts can be quantified.

Technical Guidance:

A “baseline” is a starting point or benchmark that a facility can use to compare changes over time and quantify any reduction efforts.

Baselines can be absolute or normalized. For example:

- Absolute: The total amount of water used for a period of time. (e.g., 1,500,000 of municipal water used in the reporting year)

- Normalized: The amount of water used while making a unit of product (e.g., 0.15 m3 per pair of shoes produced).

Note: It is recommended to use the ‘Normalized’ method to account for operational fluctuations. Normalized baselines provide more accurate and useful comparisons over time.

When establishing a baseline, be sure to do the following:

- Confirm the water source data is stable, and sufficient to be used to determine a baseline. In the Higg FEM, a baseline should generally comprise of a full calendar year’s data.

- Note: If your factory has undergone major structural or operational changes such as acquisition or changes in product type, in general, you should establish or reset a baseline after those changes have been completed.

- Determine if the baseline will be Absolute or Normalized (Normalized baselines are preferred)

- Verify the source data and normalizing metrics data is accurate.

- Water and production volume data from previous Higg FEM verifications, internal or external audits conducted by qualified personnel are acceptable sources of data verification.

- Apply the appropriate baseline metric (i.e., per year for absolute OR divide by the chosen normalizing metric 150,000 m3 per 1,000,000 pieces = 0.15m3/piece)

- Note: For water consumption that is not related to production, other normalizing metrics should be used where appropriate (e.g., water consumption per worker).

Note: If the baseline is used to evaluate performance against a target, the baseline should remain unchanged.

Reporting baseline data in Higg FEM:

Do:

- Review source data and raw normalizing metric data (utility invoices, meter logs, production quantity, etc.) against aggregated totals used to determine the baseline(s) to ensure they are accurate. (e.g., double check monthly water consumption records to ensure they match the annual consumption quantities used to calculate the baseline).

- Select the appropriate baseline type in the FEM – Absolute or Normalized.

- Ensure the proper units are reported and verify any unit conversions from source data to reported data.

- Enter the baseline year. This is the year the baseline data represents.

- Provide sufficient details on how the baseline was calculated (e.g., water consumption was normalized per meter of fabric produced).

- Only select Yes to the question “Was the baseline verified?” if the baseline data was fully verified in a previous Higg FEM verification, or by an internal or external audit conducted by qualified personnel.

Do Not:

- Report a baseline that is not accurate (e.g., the data source is unknown or has not been verified)

- Report a baseline that is based on insufficient data (e.g., not a full year’s data).

- Report an estimated baseline if it is not supported by verifiable and accurate estimation methodology and data (e.g., engineering calculations).

How This Will Be Verified:

When verifying a facility’s baselines, Verifiers must review:

- All source data (utility invoices, metering logs, production quantity) and aggregated data totals for the baseline year; and/or

- Records of baseline data verification where available (e.g., previous Higg Verification, data quality review, internal or external audits, etc.)

If any inconsistencies or errors are noted, the reported information must be corrected where possible and detailed comments should be included in the Verification Data field.

Full Points:

Full Points will be awarded if the facility has established baselines for all water applicable sources.

Documentation Required:

- Documentation that supports how the baseline was established for each water source. This may include:

- Water use tracking and production data from the baseline year (separated by production and domestic use, if applicable).

- Supporting calculations methodologies or assumptions used to determine the baseline.

- Supporting evidence to demonstrate how baseline data was validated (e.g., verified Higg FEM data for the baseline year, external or internal data validation process or report).

Interview Questions to Ask:

- Staff responsible for water management are able to describe how the baselines were determined including any normalizing metrics used or any assumption made in the calculation methodology.

- Relevant staff are able to describe the facility’s process to validate the accuracy of baseline data.

Inspection – Things to Physically Look For:

- The observed water management practices on-site are consistent with the facility’s reported methods for determining baselines (e.g., water sources used, water use tracking methods/equipment, etc.)

- Observations on-site do not indicate that there have been significant changes at the facility that could impact the appropriateness of the baseline (e.g., new production areas, changes to products, new buildings, etc.)

Partial Points:

- Partial points will be awarded if the facility has established baselines for one (1) or more, but not all applicable water sources.

- Have you set a baseline for this water source?

- Is this a normalized or absolute baseline?

- If normalized, are you setting separate baselines based on your facility type?

- Notes:

- This only question applies to facilities that use water in production.

- If your facility selected multiple facility types in the facility profile structure section of the FEM (e.g., Finished Product Assembler and Material Production), and you set baselines for each facility type, a separate table for baseline data will be displayed for each selected facility type.

- Notes:

Notes:

- Facilities that use water for production and do not separately track or set baselines for production and domestic water use will complete one (1) baseline table for combined production and domestic water use.

- Facilities that use water in production and separately track and have set baselines for production and domestic use separately will complete separate baseline tables for production and domestic water use.

For all water sources that have baselines, you will be asked to complete a table with the following questions based on whether the baseline is absolute or normalized:

| Absolute Baselines | Normalized Baselines |

| What is the baseline quantity for this source? | What is the baseline quantity for this source? |

| Unit of Measure | Unit of Measure |

| Enter baseline year | What is your normalized baseline based on? |

| How was your baseline calculated? | Enter baseline year. |

| Was the baseline verified? | How was your baseline calculated? |

| Provide any additional comments | Was the baseline verified? |

| Provide any additional comments |

Note: From FEM2024 onwards, in the above table, baseline data can be auto populated or manually entered in the following ways:

- New FEM Users: Required to manually input baseline.

- Existing FEM Users without a baseline: Facility can choose to:

- Enter the baseline manually OR

- Have the FEM auto populate a baseline based on the data from the previous year’s FEM.

- Existing FEM Users with an existing baseline: Baseline will auto populate based on the data from the previous year’s FEM.

Suggested Uploads:

- Documentation that supports how the baseline was established for each water source (e.g., water use tracking data and production data from the baseline year, supporting calculations or assumptions used to determine the baseline).

What is the intent of the question?

The intent of this question is for facilities to demonstrate that they have established baselines for water use at the facility so that future reduction efforts can be quantified.

Technical Guidance:

A “baseline” is a starting point or benchmark that a facility can use to compare changes over time and quantify any reduction efforts.

Baselines can be absolute or normalized. For example:

- Absolute: The total amount of water used for a period of time. (e.g., 1,500,000 of municipal water used in the reporting year)

- Normalized: The amount of water used while making a unit of product (e.g., 0.15 m3 per pair of shoes produced).

Note: It is recommended to use the ‘Normalized’ method to account for operational fluctuations. Normalized baselines provide more accurate and useful comparisons over time.

When establishing a baseline, be sure to do the following:

- Confirm the water source data is stable, and sufficient to be used to determine a baseline. In the Higg FEM, a baseline should generally comprise of a full calendar year’s data.

- Note: If your factory has undergone major structural or operational changes such as acquisition or changes in product type, in general, you should establish or reset a baseline after those changes have been completed.

- Determine if the baseline will be Absolute or Normalized (Normalized baselines are preferred)

- Verify the source data and normalizing metrics data is accurate.

- Water and production volume data from previous Higg FEM verifications, internal or external audits conducted by qualified personnel are acceptable sources of data verification.

- Apply the appropriate baseline metric (i.e., per year for absolute OR divide by the chosen normalizing metric 150,000 m3 per 1,000,000 pieces = 0.15m3/piece)

- Note: For water consumption that is not related to production, other normalizing metrics should be used where appropriate (e.g., water consumption per worker).

Note: If the baseline is used to evaluate performance against a target, the baseline should remain unchanged.

Reporting baseline data in Higg FEM:

Do:

- Review source data and raw normalizing metric data (utility invoices, meter logs, production quantity, etc.) against aggregated totals used to determine the baseline(s) to ensure they are accurate. (e.g., double check monthly water consumption records to ensure they match the annual consumption quantities used to calculate the baseline).

- Select the appropriate baseline type in the FEM – Absolute or Normalized.

- Ensure the proper units are reported and verify any unit conversions from source data to reported data.

- Enter the baseline year. This is the year the baseline data represents.

- Provide sufficient details on how the baseline was calculated (e.g., water consumption was normalized per meter of fabric produced).

- Only select Yes to the question “Was the baseline verified?” if the baseline data was fully verified in a previous Higg FEM verification, or by an internal or external audit conducted by qualified personnel.

Do Not:

- Report a baseline that is not accurate (e.g., the data source is unknown or has not been verified)

- Report a baseline that is based on insufficient data (e.g., not a full year’s data).

- Report an estimated baseline if it is not supported by verifiable and accurate estimation methodology and data (e.g., engineering calculations).

How This Will Be Verified:

When verifying a facility’s baselines, Verifiers must review:

- All source data (utility invoices, metering logs, production quantity) and aggregated data totals for the baseline year; and/or

- Records of baseline data verification where available (e.g., previous Higg Verification, data quality review, internal or external audits, etc.)

If any inconsistencies or errors are noted, the reported information must be corrected where possible and detailed comments should be included in the Verification Data field.

Full Points:

Full Points will be awarded if the facility has established baselines for all water applicable sources.

Documentation Required:

- Documentation that supports how the baseline was established for each water source. This may include:

- Water use tracking and production data from the baseline year (separated by production and domestic use, if applicable).

- Supporting calculations methodologies or assumptions used to determine the baseline.

- Supporting evidence to demonstrate how baseline data was validated (e.g., verified Higg FEM data for the baseline year, external or internal data validation process or report).

Interview Questions to Ask:

- Staff responsible for water management are able to describe how the baselines were determined including any normalizing metrics used or any assumption made in the calculation methodology.

- Relevant staff are able to describe the facility’s process to validate the accuracy of baseline data.

Inspection – Things to Physically Look For:

- The observed water management practices on-site are consistent with the facility’s reported methods for determining baselines (e.g., water sources used, water use tracking methods/equipment, etc.)

- Observations on-site do not indicate that there have been significant changes at the facility that could impact the appropriateness of the baseline (e.g., new production areas, changes to products, new buildings, etc.)

Partial Points:

- Partial points will be awarded if the facility has established baselines for one (1) or more, but not all applicable water sources.

Answer Yes if: Your facility has a current water balance or another analysis (e.g., water audit) that covers water intake, usage and output to evaluate water use at the facility.

Note: For this question “current” means that the water balance or other analysis accurately reflects facility operations and water use in the Higg FEM reporting year and was conducted no more than 5 years before the FEM reporting year (e.g., if the analysis was performed no more than 5 years before the reporting year and this reflects the facility operations and water use in the reporting year this analysis is considered acceptable).

If you select Yes, you will be asked the following sub question(s) to provide details on your water balance or other analysis:

- Which one of the below activities were conducted to evaluate and trace water intake against usage and output? Select all that apply.

- Conduct water balance / analysis.

- Please upload a copy of the water balance / analysis report

- Conduct water audit in last 5 years.

- Please upload a copy of the water audit report

- Other

- If Other, please describe.

- Please upload the methodology used for the above analysis.

- If you do not have a document to upload, describe your methodology here.

- Conduct water balance / analysis.

- From the above analysis, has your facility identified the highest water use processes or operations?

- List down the highest water use processes or operations at your facility (from highest to lowest) that account for 80% of your water use?

Suggested Uploads:

- Documentation that demonstrates the facility has conducted a water balance or other analysis to evaluate water usage at the facility (e.g., water balance or audit report, other documented methodology for analysing the water use, etc)

- Supporting documentation that shows the ranking of processes or operations based on water consumption.

What is the intent of the question?

The intent of this question is for facilities to demonstrate that a formal analysis of water use has been conducted to identify and quantify areas of significant water use or potential loss.

Technical Guidance

Understanding the production and operational aspects that influence water use at a facility allows facilities to identify and prioritize actions to reduce water use. A water balance or other water use analysis along with historical water use data and water costs will help build a facility’s understanding of overall water use factors at the facility and highlight water reduction and cost savings opportunities.

The steps below provide an overview of the key steps involved in analyzing water use at a facility:

- Data Collection: Collect information on water use (e.g., water meter readings, water bills records, process-specific water consumption data, etc.)

- Water Flow Mapping: Create a flow diagram of the facility’s water system, including water intake, usage in domestic/production processes, and discharge to wastewater treatment. This helps visualize the flow of water through the facility and identify areas of potential water loss or inefficiency.

- Measurement and Verification: Confirm the accuracy of water meter readings and other data sources and identify any discrepancies that may indicate leaks or other issues.

- Water Use Analysis: Analyze the collected data to identify patterns and trends in water use, including high water-consuming processes/equipment, seasonal variations, and areas for improvement.

Common tools used to analyse water usage at a facility include a water balance or water audit. Similar in nature, these tools can be used to quantify water intake and outputs for a facility, process/operation and/or piece of equipment. To establish a full understanding of water usage (intake and outputs) at a facility the analysis should include a focus on :

- The incoming water in the facility (e.g., the quantity and water sources)

- The quantity of water used during the production processes.

- The quantity of water recycled/reused in the facility.

- The volume of water discharged to and from any treatment systems (incoming or wastewater).

- The frequency which the analysis is reviewed and/or updated to ensure water use variability is well understood.

- Note: The more frequently a water balance/analysis is reviewed, the greater understanding one can have on facility water use and variability.

In theory, the total quantity of water influent into a facility should be equal to the total quantity discharged minus any losses (e.g., influent – effluent = 0) However, in practice, the realized difference between influent and effluent upon analysis is rarely zero. This can be due to leakage, evaporation (intended or unintended), errors in measurement, etc. Differences of less than 10-15% of total water use may be normal depending on facility operations, analysis methodology, and/or measurement techniques used, however larger differences (e.g., greater than 25% of total water) or a water balance of exactly 0 or a negative amount is usually indicative of an error. This would typically indicate a problem in the analysis or potentially due to unknown sources of water loss and should be investigated.

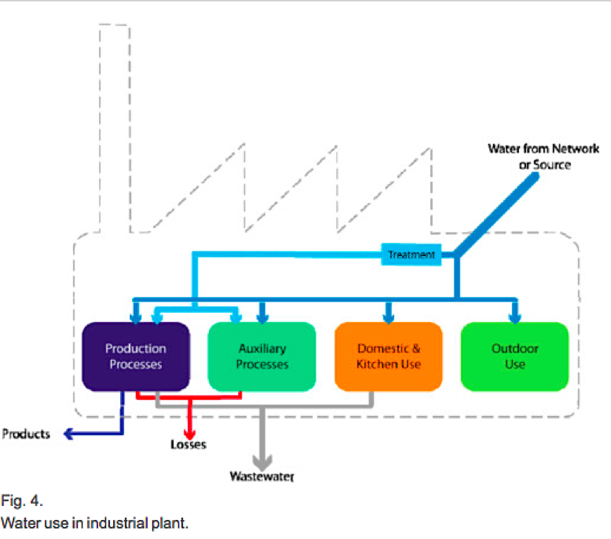

Below is an example of a basic water analysis map that shows inflows and outflows of water in a facility:

Source: http://www.sciencedirect.com/science/article/pii/S2212371716300221

Resources:

- Steps in a Water Audit http://www.facilitiesnet.com/green/article/Steps-in-a-Water-Audit-Facilities-Management-Green-Feature–9364

- Water Audit Data Collection Sheet https://www.brewersassociation.org/attachments/0001/1518/Water_Water_Audit_Data_checklist.pdf

- Water calculation tool for the textile wet processing sector https://watercalculator.dnvgl.com

- American Water Works Association (AWWA) – Water Audit Software and Guidance: https://www.awwa.org/Resources-Tools/Resource-Topics/Water-Loss-Control

How This Will Be Verified:

Full Points:

Full points will be awarded to facilities that have current water balance or another analysis (e.g., water audit) that covers water intake, usage, and output to evaluate water use at the facility that was conducted within 5 years of the FEM reporting year.

Documentation Required:

- Documentation that demonstrates the facility has conducted a water balance or other analysis to evaluate water usage at the facility. This may include:

- Water balance or water audit report

- Other documented methodology for analysing the water use.

- If applicable, supporting documentation that shows the ranking of processes or operations based on water consumption quantity (e.g., highest to lowest).

Interview Questions to Ask:

- Staff responsible for water management at the facility can explain how water usage (intake, usage, and outputs) was analysed and how the facility identifies and ranks the highest water consumption processes or operations, if applicable.

Inspection – Things to Physically Look For:

- Observations indicate that the facility’s water usage analysis (e.g., water balance or audit) is representative of current facility operations and water use observed onsite.

Partial Points: N/A

Answer

Answer

Answer Yes if: Your facility has set a target to reduce blue water use for one (1) or more sources.

Notes:

- Targets for rainwater use reductions or increases should not be reported in this question.

- If your facility has not conducted a formal evaluation of water reduction opportunities and calculated how much blue water can be reduced to support your target, you should select No for this question.

- For the definition of blue water sources, please refer to the Introduction Section of the water guidance.

If you answer Yes to this question, you will be asked to complete a series of tables with the following questions to provide details on your targets for each applicable blue water source (All applicable blue water sources will be pre-populated in the tables):

- Select all sources of blue water for which your facility has set a water reduction target.

- Have you set a target for this water source?

- Is this a normalized or absolute target?

- If normalized, are you setting separate targets based on your facility type?

- Note: If your facility selected multiple facility types in the facility profile structure section of the FEM (e.g., Finished Product Assembler and Material Production), and you set targets for each facility type, a separate table for target data will be displayed for each selected facility type.

For all sources that have targets, you will be asked to complete a table with the following questions based on whether the target is absolute or normalized:

| Absolute Targets | Normalized Targets |

| What is your target for change in water use from this source? (Enter negative value for reduction target or positive value for increased target) | What is your target for change (in %) in water use from this source? (Enter negative value for reduction target or positive value for increased target) |

| Enter the target year. | What is your normalized baseline based on? |

| Describe the measures planned to achieve this target. | Enter the target year. |

| Describe the measures planned to achieve this target |

Suggested Uploads:

- Documentation that supports how the target was established and demonstrates the target is based on a formal evaluation of reduction opportunities (e.g., water use data and baselines, new/proposed equipment specifications or work practices, etc.)

What is the intent of the question?

The intent of this question is for facilities to demonstrate that they have established formal targets to reduce blue water use at the facility.

Technical Guidance

Targets can use absolute or normalized metrics to drive quantifiable improvements by a set date compared to the baseline. For Higg FEM, reduction targets may be normalized to the production volume unit or another appropriate operational metric. A normalized target shows you when progress is real, rather than being a result of business changes such as reductions in production. An example of a normalized target is a reduction in the cubic metres of water used to produce one kilogram of sellable product (m3/kg).

When establishing formal reduction targets, be sure to do the following:

- Base the target on a formal evaluation of improvement opportunities and actions (e.g., equipment replacement or upgrades) to calculate the amount of water that can be reduced.

- For example: Setting a target based on an evaluation of installing a counter current rinsing system is expected to result in a 5% reduction in annual municipal water consumption per square meter of fabric produced that was calculated based on a formal review of the rinse system manufacturer’s specifications and the expected production requirements. OR a 10% reduction target that will be achieved by the installation of low flow water taps in all lavatories that was calculated based on the facility’s baseline water use data and the reduced flow rate of the taps to be installed.

- Define the exact target quantity, expressed as a percent (e.g., reduce normalized municipal water consumption per square meter of fabric by 5%). This must be based on a formal evaluation as noted above.

- Determine if the target will be Absolute or Normalized to a production or operating metric.

- Define the start date (i.e., “baseline”) of the target.

- Define the end date of the target, meaning the intended completion date of the required improvements.

- Define the appropriate measurement units.

- Establish procedures to review the target. This review should include an evaluation of the actions taken and progress on reaching the defined target. Quarterly reviews are recommended.

- Ensure the target is relevant to reducing the site’s water use (e.g., focuses on the most significant water uses at the site)

Reporting Targets in Higg FEM:

Do:

- Review the target to ensure all aspects noted above are covered and that the information is accurate.

- Enter the targeted reduction as a percentage. Make sure to enter a negative percentage for a reduction target (e.g. -5 for a 5% reduction).

- Provide sufficient details on how the target will be met in the “Describe the measures planned to achieve this target:” field (e.g., Achieve a 5% reduction in normalized municipal domestic water consumption per person by installing low flow fittings and self-closing taps on all taps in facility lavatories).

Do Not:

- Report a target that is not accurate (e.g., the data source is unknown or has not been verified)

- Report a target that is based on insufficient data. (e.g., a reduction target that is not based on a formal evaluation of options such as equipment upgrades to meet the stated target OR actions to meet the target have not been defined.)

- Report an estimated target if it is not supported by verifiable and accurate estimation methodology and data (e.g., engineering calculations).

How This Will Be Verified:

When verifying a facility’s targets, Verifiers must review:

- All supporting evidence (e.g., calculations, water use and baselines, new/proposed equipment specifications, etc) to verify the target is based on a formal evaluation of improvement opportunities.

- Facility operations in relation to its water sources and use to ensure targets and opportunities evaluated are relevant to the site’s water use.

If any inconsistencies or errors are noted, the reported information must be corrected where possible and detailed comments should be included in the Verification Data field.

Full Points:

Full Points will be awarded if the facility has established targets for one (1) or more blue water sources and the targets cover greater than 90% (by total blue water use in m3) of blue water used at the facility.

Documentation Required:

- Documentation that supports how the target was established for each water source and are based on a formal evaluation of reduction opportunities. This may include:

- Water tracking and production data.

- Documented evaluations of new/proposed equipment specifications, modifications to production processes or work practices that will result in water use reductions.

- Supporting calculations methodologies or assumptions used to determine the target.

Interview Questions to Ask:

- Staff responsible for water management can describe how the targets were determined including any calculations or assumptions made in the target setting methodology.

- Relevant staff can describe the facility’s proposed actions to achieve the target and how progress is monitored and tracked.

Inspection – Things to Physically Look For:

- The observed water management practices on-site are appropriate in relation to the established targets (e.g., water sources and tracking of water use, etc.)

Partial Points:

- Partial points will be awarded if the facility has established targets for one (1) or more blue water source and the targets cover 50% to 89% (by total blue water use in m3) of blue water used at the facility.

Answer

Answer Yes if: Your facility has set a target to increase grey water use for one (1) or more sources.

Notes:

- If your facility has not conducted a formal evaluation of opportunities to increase grey water use and calculated how much grey use can be increased to support your target, you should select No for this question.

- For the definition of grey water sources, please refer to the Introduction Section of the water guidance.

If you answer Yes to this question, you will be asked to complete a series of tables with the following questions to provide details on your targets for each applicable grey water source (All applicable grey water sources will be pre-populated in the tables):

- Select all sources of grey water for which your facility has set a water target.

- Have you set a target for this water source?

- Is this a normalized or absolute target?

- If normalized, are you setting separate targets based on your facility type?

- Note: If your facility selected multiple facility types in the facility profile structure section of the FEM (e.g., Finished Product Assembler and Material Production), and you set targets for each facility type, a separate table for target data will be displayed for each selected facility type.

For all sources that have targets, you will be asked to complete a table with the following questions based on whether the target is absolute or normalized:

| Absolute Targets | Normalized Targets |

| What is your target for change in water use from this source? (Enter negative value for reduction target or positive value for increased target) | What is your target for change (in %) in water use from this source? (Enter negative value for reduction target or positive value for increased target) |

| Enter the target year. | What is your normalized baseline based on? |

| Describe the measures planned to achieve this target. | Enter the target year. |

| Describe the measures planned to achieve this target |

Suggested Uploads:

- Documentation that supports how the target was established and demonstrates the target is based on a formal evaluation of opportunities to increase grey water use (e.g., water use data and baselines, new/proposed equipment specifications or work practices, etc.)

What is the intent of the question?

The intent of this question is for facilities to demonstrate that they have established formal targets to increase grey water use at the facility.

Technical Guidance

Increasing the use of grey water through recycling and reuse programs allows a facility to reduce the amount of blue water used at the facility and supports efforts towards a closed loop system that reduces overall water consumption.

Targets can use absolute or normalized metrics to drive quantifiable improvements by a set date compared to the baseline. For Higg FEM, targets to increase grey water use may be normalized to the production volume unit or another appropriate operational metric. A normalized target shows you when progress is real, rather than being a result of business changes such as variation in production. An example of a normalized target is an increase in the cubic metres of grey water used per employee per day for domestic use (e.g., toilet flushing) (m3/employee per day).

When establishing formal targets to increase grey water use, be sure to do the following:

- Base the target on a formal evaluation of improvement opportunities and actions (e.g., equipment replacement or upgrades) to calculate the increase in the amount of grey water used.

- For example: Setting a target based on an evaluation of installing a grey water recycling system is expected to result in a 5% in grey water use per employee per day that was calculated based on a formal review of the system manufacturer’s specifications and the grey water usage baseline.

- Define the exact target quantity, expressed as a percent (e.g., increase the amount of grey water recycled and used per piece in the screen washing department by 5%). This must be based on a formal evaluation as noted above.

- Determine if the target will be Absolute or Normalized to a production or operating metric.

- Define the start date (i.e., “baseline”) of the target.

- Define the end date of the target, meaning the intended completion date of the required improvements.

- Define the appropriate measurement units.

- Establish procedures to review the target. This review should include an evaluation of the actions taken and progress on reaching the defined target. Quarterly reviews are recommended.

- Ensure the target is relevant to increasing the site’s grey water use.

Reporting Targets in Higg FEM:

Do:

- Review the target to ensure all aspects noted above are covered and that the information is accurate.

- Enter the targeted increase as a percentage. Make sure to enter a positive percentage for a target to increase use (e.g., 5 for a 5% increase).

- Provide sufficient details on how the target will be met in the “Describe the measures planned to achieve this target:” field (e.g., Achieve a 20% increase in grey re-use per person by installing a grey water recycling system in facility lavatories).

Do Not:

- Report a target that is not accurate (e.g., the data source is unknown or has not been verified)

- Report a target that is based on insufficient data. (e.g., a target that is not based on a formal evaluation of options such as equipment upgrades to meet the stated target OR actions to meet the target have not been defined.)

- Report an estimated target if it is not supported by verifiable and accurate estimation methodology and data (e.g., engineering calculations).

How This Will Be Verified:

When verifying a facility’s targets, Verifiers must review:

- All supporting evidence (e.g., calculations, grey water use and baselines, new/proposed equipment specifications, etc) to verify target is based on a formal evaluation of improvement opportunities.

- Facility operations in relation to its water sources and use to ensure targets and opportunities evaluated are relevant to the site’s water use.

If any inconsistencies or errors are noted, the reported information must be corrected where possible and detailed comments should be included in the Verification Data field.

Full Points: