Higg FEM How to Higg Guide 2022

Table of Contents

General Introduction

Wastewater can be a significant contributor of pollution and contamination for surrounding natural systems and communities if not managed, treated and discharged properly. All facilities have some form of wastewater:- Domestic use: toilets, showers, kitchens, cleaning, etc.

- Industrial use: production, lubrication, cooling, maintenance, cleaning of production machines, etc.

Before answering assessment questions, you will first be asked to define your facility’s approach to wastewater treatment and discharge. The following use and treatment methods will determine which Wastewater questions will need to be submitted for your facility:

- Industrial and/or domestic wastewater?

- Offsite treatment, onsite treatment, both onsite and offsite treatment, or Zero Liquid Discharge?

The Higg Wastewater section requires you to:

- Track quantity of wastewater generated from industrial and/or domestic operations

- Report all wastewater quality parameters that were found to not meet permits or industry standard(s), such as the ZDHC Wastewater Guideline, in the most recent quality test

- New guidance for Hardgoods facilities: Whilst the ZDHC Wastewater Guideline are not directly applicable to hardgoods manufacturers, they are encouraged to make reference to it where appropriate or adopt equivalent industry best practice.

- Report name and quality results from the offsite wastewater treatment plant (if applicable)

- Describe backup process if regular treatment fails (if applicable)

- Ensure proper sludge disposal (if applicable)

- Report whether your site reuses and/or recycles process wastewater as process water (if applicable)

Wastewater Introduction

This section refers to water leaving a site that is not intended for reuse within your facility. Wastewater can be a significant cause of environmental pollution if not handled, stored, transferred, treated, and/or disposed of appropriately.

If your facility uses water for any aspect of its operations, there will be some form of industrial wastewater or liquid discharge. This includes all manufacturing and/or commercial activities within your facility site’s footprint, such as industrial processing, lubrication, cooling, maintenance, cleaning, and domestic use (e.g., dormitories, bathrooms, showers, kitchens). If any of these exist within a facility then the site has some form of wastewater and associated discharges and effluents.

Wastewater discharge can take on many forms:

- process (or “trade”) effluents arising from various stages of an industrial, agricultural, or commercial process;

- cooling wastewater or other non‐contact wastewater (e.g., flushing chillers);

- blow‐down (e.g., from compressors, boilers);

- sanitary / domestic wastewater (e.g., from toilets, sinks etc.).

Other types of liquid discharge include:

- storm water run‐off (sometimes referred to as surface water run‐off) from roofs, hard standing areas, car parks, etc.);

- firewater (water run-off from fire fighting drills)

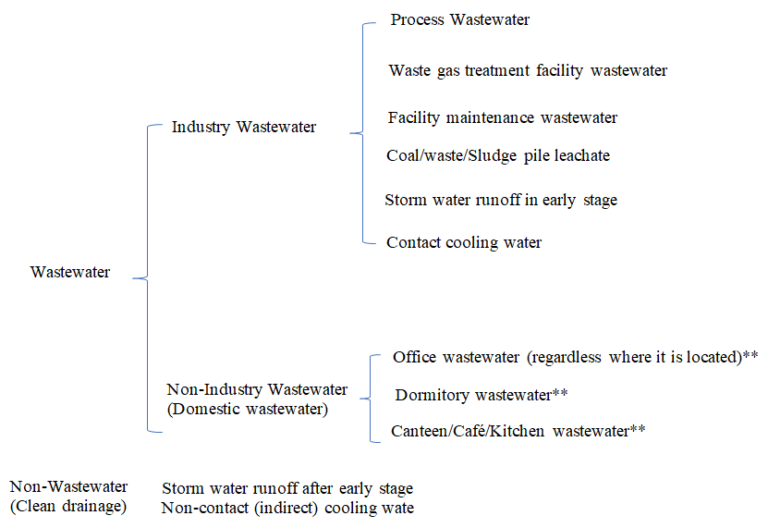

A frequently asked question asks “how to categorize my wastewater as either industrial or domestic. Below is a diagram to help you decide, along with some notes for situations where it still may not be clear.

Decisions about the most appropriate or efficient options for managing wastewater (e.g. on‐site treatment, off‐site treatment options for reuse, etc.) will depend on a number of factors, including:

- Facility location

- External infrastructure availability

- Volume of wastewater generated

- Composition of wastewater

- On‐site (or off‐site) reuse of treated wastewater

- Cost

- Local regulatory requirements

The quantity and quality of the wastewater to be treated will influence/govern the treatment or disposal options for that wastewater stream. For example, there can be significant differences in:

- Wastewater volume and flow rate

- Total suspended solids (TSS) content

- Biological oxygen demand (BOD)

- Chemical oxygen demand (COD)

- Potential Toxicity (e.g. from chemicals, medicines/antibiotics etc.)

- Heavy metal content (e.g. antimony, arsenic, cadmium, chromium, cobalt, copper, cyanide, lead, mercury, nickel, zinc, etc.)

- pH (acidity / alkalinity)

- Color

- Temperature

- Surfactants

- Nitrogen and phosphorous content

- Oil and grease, amongst other

New Guidance for Hardgoods facilities:

Hardgoods facilities may have several specific contaminants that are covered in the groups mentioned above.

A few examples are:

- Organic solvents (measured by BOD, COD, or specific wastewater parameter)

- Degreasing agents (measured by BOD, COD, or specific wastewater parameter)

- Heavy metals from the metal treatment processes (heavy metals, pH, temperature.)

On-site wastewater treatment is the wastewater treatment plant used and managed by the factory only. After treated by the on-site treatment, the wastewater can meet with relevant limits and be directly discharged into the environment, or into an Off-site 3rd party treatment plant (known as partial onsite treatment).

Off-site wastewater treatment is a third party enterprise or organization who provides wastewater treatment service for more than two pollutant discharging entities by collecting their wastewater, and the wastewater discharged directly to the environment should meet with the relevant limits. The off-site treatment can be public wastewater treatment facility, regional wastewater treatment facility (i.e. industrial park, industry area, etc.)

Zero-liquid discharge (ZLD) is a treatment process that design for no water leaves a facility in liquid form. At a facility with on-site ZLD treatment system, almost all wastewater is treated and recovered such that the only water discharged from the facility exists by evaporation or as moisture in the sludge from treatment plant operations. (Source: https://www.roadmaptozero.com/output – see definitions section of ZDHC Wastewater Guidelines). A facility is not considered to have a ZLD treatment system if there is a liquid discharge.

Reference to Industry Standards

One of our partner organizations, the Zero Discharge of Hazardous Chemicals (ZDHC) group, has developed a Wastewater Guideline for our industry to use as a guideline to manage wastewater and drive the industry toward the goal of zero discharge of hazardous chemicals. In Higg FEM 3.0 you will find mention of industry standards, and the ZDHC Wastewater Guideline is one of such standards.

New guidance for Hardgoods facilities: Whilst the ZDHC Wastewater Guideline are not directly applicable to hardgoods manufacturers, they are encouraged to make reference to it where appropriate or adopt equivalent industry best practice.

Applicability Questions

Does your facility generate industrial wastewater?

Review the definition of industrial wastewater in the introductory paragraphs above.

Does your facility have Zero Liquid Discharge?

Review the definition of ZLD in the introductory paragraphs above.

Do you treat industrial and domestic wastewater together?

Review the definition for industrial and domestic wastewater in the introductory paragraphs above.

Where is your industrial/domestic/combined wastewater treated?

Review the definitions of on-site and off-site wastewater treatment in the introductory paragraphs above.

Wastewater – Level 1

Questions

- What was the total quantity of wastewater discharged from your facility during this reporting year?

- Which method was used to track wastewater volume?

- What was the frequency of measurement?

- How many wastewater discharge points do you have?

- Have you labelled all wastewater discharge points?

- Do you monitor all identified wastewater discharge points?

- What was the final discharge point for your facility’s wastewater?

- Provide any additional comments

Suggested Upload: Annual wastewater discharge monitoring record (quantity)

Wastewater tracking should include water that is either discharged out from the facility, reclaimed/recycled or reused at your site

Industrial: include all manufacturing and/or commercial activities within your facility site such as industrial processing, lubrication, maintenance etc.

Domestic: include all domestic wastewater generation including wastewater/effluent from dormitories, bathrooms, showers, and kitchens, etc.

What is the intent of the question?

The intent of this question is to ensure that the site knows how much wastewater is being produced and where it is discharged to. This information can be derived from the facility’s water balance. By answering this question, facilities can demonstrate how they monitor and manage wastewater volume. Knowing your volume is an important first step to making decisions on appropriate treatment options.

Wastewater tracking allows complete visibility into daily operations of a facility and what operations impact wastewater volumes. Knowing your wastewater volume is directly linked to ecological impact and operational costs.

Technical Guidance:

Wastewater tracking should include both domestic and industrial wastewater where applicable and include water that is either discharged, reclaimed/recycled or reused at your site, that is generated from all manufacturing and/or commercial activities within your facility.

When tracking wastewater, it’s recommended to start by:

- Mapping out facility areas and processes to identify where wastewater is generated and discharged.

- Establish procedures to collect and track wastewater data:

- Install on-site meters or use metered invoices from off-site treatment facilities.

- If estimation techniques are used to determine the amount of wastewater generated, the calculation methodology should be clearly defined and be supported by verifiable data.

- Record tracking data (e.g. daily, weekly, monthly records) in a format that is easy to review [e.g. spreadsheet (e.g. Microsoft Excel) or similar data analytics program that allows export of data in a human readable format (e.g. Excel, csv)] and maintain relevant supporting evidence for review during verification.

Tracking Wastewater Volume

The most accurate way to track wastewater volume is using a metering system. Mechanical meters and ultrasonic meters are widely used to track wastewater volume. Facility should install meters at all wastewater discharge points before discharging to the environment. If the facility has its own effluent treatment plant (ETP), the meter should be installed at the outlet of the wastewater treatment facility. Facility needs to gather and record data from the meters regularly in order to track accurate wastewater discharge volume. The method applies to both domestic and industrial wastewater.

If facility does not have meters to track its wastewater discharge volume, an estimation method can be used which may include any of the following estimation techniques listed below. Note: If your facility does not track wastewater via metering or invoices and calculates your annual wastewater discharge volume using an estimation methodology, then you must select “Estimates” for the question “Which method was used to track wastewater volume?”

- If the facility has accurate data (meters or invoices) on incoming water volume for production process and domestic use, the facility may estimate wastewater discharge volume using the incoming water volume. The facility may need to account for water use or loss for things like cooling tower evaporation loss or irrigation when estimating wastewater volume.

- Use of any official environmental reports that contain data on wastewater discharge volume (e.g. Environmental Impact Assessment reports, Environmental permit applications, Government’s compliance report or offsite wastewater treatment invoices). Note: In some cases, wastewater treatment invoices from offsite wastewater treatment facility may not provide the treated wastewater volume. Instead, the invoice would indicate the total treatment fee (e.g. 100 USD) with unit treatment cost ($1 USD/m3). In this case, facility may need to manually calculate and record wastewater volume with the total treatment fee and unit cost (e.g. total treatment fee ÷ unit treatment cost = wastewater volume).

- If the facility has no documentation which indicates the amount of incoming water, then they can estimate industrial wastewater volume based on different production processes and equipment specific consumption. For example, in a dyeing mill, the dyeing recipe may have water needed for each dyeing batch, or the dyeing machine may also have specifications on how much water is required for each batch. Facility would need to collect production volume of each dyeing recipe and production volume of each dyeing machine. Then the facility would be able to manually calculate using production water use of each recipe per machine and water needed of each recipe/machine, multiply by respective production volume. Lastly, sum up all production water use. This estimated production water volume could be considered as an estimation for the amount of industrial wastewater discharged. Facilities may also need to account for any loss due to evaporation during production processes.

A tool available to help calculate water use from different sources can be found here: http://waterplanner.gemi.org/calc-waterbalance.asp

Domestic Wastewater Tracking (including Septic Systems):

Tracking flow rate and discharge volume of domestic wastewater with on-site meters is not a common practice but it is highly encouraged to track the volume and quantity of the domestic wastewater. The behavior we are looking for with asking this is to show that a facility understands how much water is being wasted/ leaving their facility and they are applying that volume to an assessment of water use in your facility and the impact it creates to the environment if not properly treated.

If domestic wastewater discharge metering data or actual discharge data is not available, factory could consider estimating wastewater discharge based on the sites total water use, the estimated amount used for domestic purposes and then minus an estimated amount due to losses (e.g. evaporation). For example, a site with domestic only wastewater who used 150m3 of municipal water per month estimates that 10% of the water is lost due to evaporation and leaks would report 135m3 of wastewater discharged (150m3 – 10%).

Water use in a facility can also be estimated by number of persons, number and types of facilities, taps, toilets, shower, irrigation etc based on any available local/regional data or manufacturer’s specifications (e.g. rated litres per flush for toilet fixtures).

Note: If an estimation technique is used, this should be fully documented, applied consistently and based on reasonable estimation factors that are derived from relevant sources (e.g. manufacturer’s specifications, regional data on sewerage volume per person/day, etc.)

Reporting wastewater data in the FEM:

Before reporting wastewater data in the FEM, data quality checks should be performed to ensure that the data AND the processes used to collect and record the data are effective at producing accurate data.

Do:

- Review source data (e.g. meter logs, invoices, etc) against aggregated totals to ensure it is accurate.

- Compare the current year with historical data. Any significant changes (e.g. an increase or decrease of over 10%) should be attributable to known changes. If not, further investigation may be warranted.

- Ensure the most recent and updated versions of data tracking spreadsheets are being used and that all automated calculations/formulas are correct.

- Ensure the proper units are reported and verify any unit conversions from source data to reported data. Note: The FEM requires that wastewater data be entered in cubic meters (m3).

- Report the data source (e.g. meters, invoice, estimate) and frequency of measurement (e.g. daily, monthly, etc).

- Report the final discharge point (e.g. Offsite Wastewater Treatment Plant). Note: This should be where the wastewater is discharged to after it leaves the facility.

- Review any assumption or estimation methodology/calculations to ensure accuracy.

- Add notes in the “Provide any additional comments” field to describe any data assumptions, estimation methodology, or other relevant comments on the reported quantity.

Do Not:

- Report data that is not accurate (e.g. the data source is unknown or has not been verified).

- Report estimated data if it is not supported by verifiable and reasonably accurate estimation methodology and data (e.g. engineering calculations).

How This Will Be Verified:

When verifying a facility’s wastewater data, Verifiers must review all aspects of the facility’s wastewater tracking program that could produce inaccuracies including:

- The initial data collection processes and data sources (e.g., invoices, on-site meters, metering logs, etc.); and

- The process and tools used to aggregate the data (e.g. spreadsheet calculations, unit conversions, etc.)

If any inconsistencies or errors are noted, the reported information must be corrected where possible and detailed comments should be included in the Verification Data field.

Yes

- Documentation Required:

- Wastewater discharge records (e.g. monthly bills and annual discharge records; metering records compiled in a spreadsheet (e.g. Excel) is ok as long as the metering records are available for review as well) whose totals match the reported data to all questions answered.

- Meter calibration records where applicable (e.g. as per manufacturer’s specifications).

- Estimation methodology documented where applicable

- All wastewater sources at the facility are tracked in full. This means that all sources listed in the Level 1 table have complete answers in all columns that are accurate.

- Interview Questions to Ask:

- Key Employees are aware of the facility’s wastewater data tracking program and how data quality is maintained.

- Inspection – Things to Physically Look For:

- Is wastewater/effluent directed to a wastewater/effluent treatment plant or does it undergo treatment prior to discharge?

- Are surface water/storm water drains free from contamination and blockages?

- Are procedures established to manage wastewater/wastewater discharges being followed? (e.g. management of wastewater, activities etc.)

- Are spills or leaks to the environment observed?

- Are there boiler blow down and other membrane cleaning activities where water is collected and tracked as well?

- Are the flowmeters in place working (in case the facility has selected the “meters” method), calibrated and accessible?

- A picture of flowmeters as evidence has to be taken during the site inspection

- In the case of estimated data, please verify the water balance is based on available flow meters, equalization tank volumes, flow rate timing, etc.

Verify invoices for incoming water and discharge estimation

Suggested Upload: Process Flow Diagram and Utility Map that show where pipes and sewers and how they are connected.

This question is not scored in 2020 Higg FEM, 2021 Higg FEM and 2022 Higg FEM reporting year. Score may be applied in future reporting years.

What is the intent of the question?

It is considered good to separate stormwater from wastewater for many reasons including greater control of volume surges and pollutant loading on wastewater treatment systems as well as prevention of overflows that release sewage and/or untreated industrial wastewaters to the environment. Facilities should have separation of these two systems through the facility, but local regulations may stipulate what must be done in terms of treatment prior to discharge, which can include combining stormwater with facility wastewater in a treatment system.

Technical Guidance:

Stormwater (e.g. rain water) and wastewater should be collected, treated and discharged separately, so as to reduce the impact of stormwater on wastewater treatment plant and ensure treatment efficacy. The purpose of having this mechanism is to ensure stormwater and wastewater are collected and discharged accordingly, and to ensure the system is functional.

How to maintain the mechanism –

1) Code and label all the stormwater and wastewater collection points and drainage systems, and assign designated responsible department or person for regular management

2) Develop a stormwater and wastewater drainage map with the information of location, uses, code and responsible person. Post the drainage map in a location where it is accessible for most of the employees. Note: The facility’s wastewater collection and stormwater drainage system may be included on facility structural engineering/utility drawings.

3) Provide training to all responsible persons on the different uses of each collection system.

4) Regularly check (e.g. daily, monthly, etc) on all stormwater and wastewater collection points and drainage systems to ensure there is no mixing or damage to the systems.

How This Will Be Verified:

Yes

- Documentation Required:

- Stormwater and wastewater drainage map(s) that shows the two collection and drainage systems are separate

- Documented policies or procedures, and regular monitoring records if available

- Interview Questions to Ask:

- Interview employees who manage various wastewater/stormwater related infrastructure that has potential to cross contaminate or leak including pipes, chemical tanks, and other systems.

- Determine if employees perform inspections walks, document findings, and resolution of findings.

- Inspection – Things to Physically Look For:

- Obtain the Utility map and Process Flow Diagram, walk a few lines on the map to inspect for accuracy.

- Review permit or other regulatory information around combined sewers and/or separation of stormwater and any stormwater treatment prior to discharge regulations.

- Check and observe the stormwater well if there is anything unusual, i.e. if it is not raining but there is wastewater flowing by the well, or water in the rainwater well is with suspicious color (white, black, green, etc.).

- Name:

- Address:

- Ownership:

- Do you have a copy of the contract with the wastewater treatment plant?

- Please upload documentation if available

Upload: a) Signed contract with the off-site wastewater treatment plant; b) A permit and contractual agreement for your facility to show that they are allowed to discharge into the off-site wastewater treatment plant

This information is important because environmental contamination from improper treatment must be addressed regardless of where the problem originates. This information can help your factory, the community, and local businesses prevent or cleanup accidental environmental contamination in the case of a failure.

You will receive Full Points if you know information of your off-site wastewater treatment plant and are able to upload a contract. Please note that a contract will be required during verification for all factories in China.

What is the intent of the question?

The intent of this question is for the facility to have a relationship and be able to communicate with the wastewater treatment plant. This also enables troubleshooting and supports continuous improvement.

This information is important because environmental contamination from treatment problems must be addressed regardless of where the problem originates. This information can help the community and businesses prevent or cleanup accidental environmental contamination in the case of a failure.

How This Will Be Verified:

Yes

- Documentation Required – already checked during permit section:

- Signed contract with the off-site wastewater treatment plant

- A permit for your facility to show that you are allowed to discharge into the off-site wastewater treatment plant

- Interview Questions to Ask:

- Check for basic details of the off-site wastewater treatment plant like layout, treatment type (primary, secondary, tertiary), etc.

- Does management have a process in place to renew the contract with the 3rd party off site treatment plant?

Does your facility have a process to contact appropriate government authorities or agencies as legally required in case of accidental discharge?

Does your facility provide training to all relevant employees regarding the backup plan?

- How many employees were trained?

- How frequently do you train your employees?

Select all strategies included in your facility’s back-up plan for wastewater

- Emergency Production Shutdown

- Holding Tank

- What is the size of your facility’s holding tank?

- Secondary Treatment (biological and advanced chemical treatment—excluding coagulation, flocculation, neutralization, clarification/sedimentation process)

- Discharge to Offsite Water Treatment Plant

- Other Backup Process

What is your facility’s wastewater treatment handling peak / max average capacity?

Upload: Documented emergency backup process that is sufficient to treat the average daily amount of wastewater discharged by the facility site.

It is critical that your facility has a backup plan in the event of a wastewater treatment failure in order to prevent untreated effluent from being discharged to the local environment. If you do not have a backup process that can handle your average daily capacity, you cannot score points or complete Level 1.

What is the intent of the question?

This question promotes a contingency plan in the event the treatment process fails to prevent untreated effluent from being discharged. If you do not have a backup process in place, you cannot complete Level 1 as this is critical to preventing accidental environmental contamination in the case of a failure.

This is critical to prevent accidental environmental contamination in the case of a failure of wastewater treatment plant.

Technical Guidance:

The facility needs to set up and document a contingency plan in response to emergencies. It is important to know the wastewater treatment handling capacity per day and the size of the holding tank (if the facility has a holding tank). This information should be compared with wastewater quantities to determine whether you can hold the wastewater during an emergency. Holding tanks should not be considered as an exclusive backup measure.

The type of responses could be:

- Facility has an additional holding tank which can hold the quantity of wastewater equal to one day’s production as a minimum. (This is the case if the facility is not doing any treatment but directly sending the waste water to CETP as a continuous discharge through a pipeline.)

- In cases if the facility is doing pre-treatment in-house in order to meet the contractual requirements with the CETP on the quality of the wastewater discharged, then they should have a collection tank followed by homogenization or neutralization etc. In those cases, the facility should have a larger collection tank with capacity to hold more than the volume of the wastewater generated currently, and it should additionally hold at least 1 day’s production volume in addition to the existing volume or residence time.

- The facility will shut down the production until the situation is back to normal. However, this response should be backed up by some kind of documented emergency response process rather than stating simply that they will stop production.

Without having a documented emergency response plan and having this understood across all teams, it is not possible to move past level 1 because the main intention of this practice is that no wastewater should is bypassed or discharged to any body of water without proper treatment.

How This Will Be Verified:

Yes

- Documentation Required:

- Documented backup process that is sufficient to treat the average daily amount of wastewater discharged by the facility site. This should outline either the emergency production shutdown procedures or/and the type of treatment, availability of treatment, procedures for putting back up treatment into operation, responsible person or people for delivering these operations, etc.

- Any schematics describing the backup treatment options and capacity

- Interview Questions to Ask:

- The key employee responsible for the wastewater treatment can articulate what the back-up plan is and demonstrate how and when it would be put into effect

- Has this back up system been needed? When and why?

- If any emergency event happened before, when and why was the back-up system needed? Was the backup plan sufficient to manage the emergency situation?

- Inspection – Things to Physically Look For:

- Request the documented back up plan and verify if the area is preset as per the plan

- Take a picture of the plan, equipment (if on-site), and/or contract (if off-site)

This question is not scored in 2020 Higg FEM, 2021 Higg FEM and 2022 Higg FEM reporting year. Score may be applied in future reporting years.

What is the intent of the question?

Factories should be monitoring wastewater discharge and reduce the pollutants of wastewater to levels compliant with applicable laws and regulations.

The intent is to assess a factories knowledge of their process flow diagram in terms of the piping and other conveyance systems used for distributing water and directing wastewater flows to the correct treatment or discharge locations. A facility should show environmental management systems around inspections to continue to confirm there are no illicit discharges.

Technical Guidance:

Identify and characterize all wastewater streams, and maintain an inventory of process wastewater streams and ensure they are directed to appropriate treatment before being discharged to the environment.

Install and maintain appropriately sized wastewater treatment systems that reduce the pollutant of wastewater to levels compliant with applicable laws and regulations.

In the absence of an on-site wastewater treatment facility, discharge wastewater into the off-site wastewater treatment facility (i.e. industrial park wastewater treatment facility, or municipal wastewater treatment facility) as regulated. Required discharge permits must be updated periodically and filed with the proper regulatory agency.

Prepare for emergencies and implement emergency response actions in case the on-site wastewater treatment plant exceeds its capacity or if it malfunctions.

Provide training for all employees who work directly with wastewater.

How This Will Be Verified:

Yes

- Documentation Required:

- Review documentation to record what inspections are done, where they are done, and the frequency to monitor for leaks and bypasses.

- Compare operation and monitoring records of wastewater treatment plant.

- g. Influent/Effluent records, online monitoring system records and other system records to check if the difference between amount of wastewater generated and discharged is acceptable.

- Interview Questions to Ask:

- Interview employees who manage various outdoor manufacturing infrastructure that has potential to leak including pipes, chemical tanks, and other systems.

- Determine if employees perform inspection walks, document findings, and resolution of findings.

- Interview employees in production workshop to check if they are aware of wastewater collection and treatment.

- Interview employees in wastewater treatment plant and labs to understand daily operation practice, training and awareness.

- Inspection – Things to Physically Look For:

- Obtain the Utility map and Process Flow Diagram, walk a few lines on the map to inspect for accuracy.

- Walk the exterior around key systems and buildings to look for illicit discharges.

- Check the wastewater and rainwater discharge point if there is wastewater leaking or bypassing.

- Check the wastewater treatment plant if each part is functional and well-maintained.

Does your facility provide training to all relevant employees regarding the disposal method of hazardous sludge?

- How many employees were trained?

- How frequently do you train your employees?

How is your hazardous sludge disposed of?

- Hazardous Waste Treatment

- Incinerated controlled conditions

- Landfilled

- Open burning

- Fuel Blended

- Composted

- Fertilizer (applied to land)

Upload: a) Sludge analysis or test results from last 12 months (if non-hazardous is selected); b) permits or manifests for proper disposal or land application.

If you have hazardous sludge it must be disposed of through a licensed hazardous waste contractor or through incineration under properly controlled conditions.

What is the intent of the question?

You should know if there are any chemical or industrial hazards present in your operations, and, if there are, you need to make sure you do not dispose of these hazards improperly.

Hazardous sludge needs to be disposed of properly to avoid contaminating the environment. If you put hazardous sludge onto land or burn it openly, you can release serious hazards into the environment.

Technical Guidance:

Sludge should be properly disposed through authorized agent or facility should be licensed by local pollution board to decompose it in premises. Chemicals should be handled and disposed of in accordance with MSDS section 13. In cases where the local government has classified the sludge under non-hazardous waste then the test report of sludge analysis may not be necessary. However, landfilling and open burning activity in-house may not be appropriate unless it is clearly identified through sludge analysis that the sludge is non-hazardous in nature.

How This Will Be Verified:

Yes

- Documentation Required:

- An inventory of the amounts and types (non-hazardous and hazardous) sludge generated

- Lab analyses showing the non-hazardous and hazardous (if applicable) components for the various types of sludge

- Documentation showing methods for disposing each type of sludge

- For off-site disposal, invoices or delivery records confirming that the types of disposal selected here reflect what’s being used in practice

- If disposal is done via landfilling, open burning, compost, fuel blended, or as fertilizer applied to land, the sludge must be analyzed and documented as non-hazardous and suitable for the particular disposal method

- Permits, if applicable for a particular disposal method

- Interview Questions to Ask:

- Is there an in-depth and up-to-date knowledge of the sludge components? How is sludge regularly analyzed to ensure it is properly disposed of?

- Is management and responsible employees aware of proper disposal methods for each type of sludge?

- Inspection – Things to Physically Look For:

- Site or area and process for disposing of sludge if it is one on-site

- Please take photographs

Non-hazardous sludge can be disposed of through any method though you must provide documented evidence that your facility’s sludge is not hazardous.

What is the intent of the question?

You should know if there are any chemical or industrial hazards present in your operations, and, if there are, you need to make sure you do not dispose of these hazards improperly.

Technical Guidance:

Sludge should be properly disposed through authorized agent or facility should be licensed by local pollution board to decompose it in premises.

How This Will Be Verified:

Yes

- Documentation Required:

- An inventory of the amounts and types (non-hazardous and hazardous) sludge generated

- Lab analyses showing the non-hazardous and hazardous (if applicable) components for the various types of sludge

- Documentation showing methods for disposing each type of sludge

- For off-site disposal, invoices or delivery records confirming that the types of disposal selected here reflect what’s being used in practice

- If disposal is done via landfilling, open burning, compost, fuel blended, or as fertilizer applied to land, the sludge must be analyzed and documented as non-hazardous and suitable for the particular disposal method.

- Permits, if applicable for a particular disposal method

- Interview Questions to Ask:

- Is there an in-depth and up-to-date knowledge of the sludge components? How is sludge regularly analyzed to ensure it is properly disposed of?

- Is management and responsible employees aware of proper disposal methods for each type of sludge

- Inspection – Things to Physically Look For:

- Site or area and process for disposing of sludge if it is one on-site

- Please take photographs

Suggested Upload: a) Documentation that your facility treats septic wastewater before it is discharged; b) Plan to upgrade your septic tank to a more modern wastewater treatment approach.

Does your facility provide training to all relevant employees regarding the disposal method of septic waste?

- How many employees were trained?

- How frequently do you train your employees?

How does your site unload your septic tank once full?

- Describe where it is discharged

- Describe how it is treated after discharge

Please upload documentation if available

Do you have a plan to upgrade your septic tank to a more modern wastewater treatment approach?

Septic wastewater needs to be treated and disposed of properly to avoid contaminating the environment.

Your facility should begin planning to upgrade your septic system to a more modern form of treatment in order to properly contain pollutants long-term. You will be awarded partial points if you are properly treating and disposing of septic wastewater, but do not yet have a plan to upgrade to a modern treatment system.

What is the intent of the question?

You should know if there are any chemical or industrial hazards present in your operations, and, if there are, you need to make sure you do dispose of these hazards properly.

Septic wastewater needs to be disposed of properly to avoid contaminating the environment.

If you do not treat or discharge your septic wastewater properly, you will release hazards into the environment.

Technical Guidance:

Domestic water uses such as washing detergent, floor cleaning chemicals and spot cleaners, other janitorial chemicals may lead to discharge of few regulated chemicals and high amounts of coliform. A facility should understand, monitor and account for the associated risk of discharging septic wastewater by the following activities:

- Establish a process to ensure that septic wastewater is treated before it is discharged.

- Appoint a responsible person to manage and monitor the septic wastewater

- Contract with approved third party to unload the septic tank contents and keep the disposal record/ invoices

How This Will Be Verified:

Full Points

- Documentation Required:

- Documentation (process, schematics of equipment, procedures, responsible persons, etc.) that site treats septic wastewater before it is discharged

- Documentation describing how the you unload the septic tank and dispose of the waste once full

- Any permits if required

- Disposal records/invoices for septic tank contents removal if applicable

- A time-bound plan that describes the details and milestones for how you are or will be upgrading your septic tank to a more modern wastewater treatment approach

- Interview Questions to Ask:

- Management and responsible employees can describe what specific waste water gets treated in the septic system

- Management and responsible employees can describe how the site unloads the septic tank once it is full and can tell you roughly how often this procedure is done.

- Management and responsible employees can describe where septic tank discharge is treated and/or disposed of once removed from the tank

- Management can speak to plan to their plans upgrade to a more modern wastewater treatment approach and provide their timeframe for doing this

- Inspection – Things to Physically Look For:

- Take pictures of the septic tank area and sewage pipelines

- Do the pictures match their plans provided

- Is there evidence of improper disposal of septic waste or overburdened septic systems? If yes, please make comments and take photos.

Partial Points

- Same as what is required for “yes” except for plans about upgrading from a septic system

Wastewater – Level 2

Questions

Are you reporting against this standard?

- ZDHC Wastewater Guideline

- BSR

- IPE

- Customer/Brand

- If other, please describe (excluding local law and regulations)

- Have you tested and met all parameters specified in the standard?

- Are your parameter results available on the standard’s platform? (e.g. ZDHC Gateway or IPE database)

If ZDHC Wastewater Guideline was selected:

- Does your test result also show no detection of parameters in Table 2A-N Chemical Groups?

Upload test results

Complete parameters tables if detected

What is the intent of the question?

This question is intended to demonstrate a facility’s current performance with wastewater quality through wastewater standards tracking and reporting. The standards referred here are industry standards and the intention is to improve beyond compliance against local law and regulations.

The quality of the water discharged by your facility is directly linked to ecological impact and operational costs. It also is directly related to compliance at a facility along with potential disclosure requirements for industry organization transparency.

What is the optional ZDHC Wastewater Guideline?

The Zero Discharge of Hazardous Chemicals (ZDHC) Wastewater Guideline is an OPTIONAL guideline that some brands are requiring of their customers. If you have not heard of ZDHC from your customers, please disregard this reference – you will not be penalized if you do not answer the last column in the parameters table.

The Zero Discharge of Hazardous Chemicals (ZDHC) Programme is a collaboration of brands, value chain affiliates and associates that releases a ZDHC Wastewater Guideline, which is a unified expectation on wastewater quality for the entire textile and footwear industry. If you would like more information on ZDHC, you may peruse their website and guideline here: https://www.roadmaptozero.com/about

Technical Guidance:

1) Report all parameters for which you have found a detection / are over the limit from the test reports generated from 3rd party approved laboratories during previous year or inhouse monitoring reports. We only are seeking to collect information on wastewater problems in order to prioritize action rather than incentivize data reporting.

- Select standard used

- Enter results for parameters not met (type number and select unit).

- Enter limit required by the permit or standard (e.g., limits listed in ZDHC Wastewater Guideline at Foundational level)

- If you choose ZDHC Wastewater Standard, you will be asked an additional set of UNSCORED questions about whether test parameters listed in the ZDHC Wastewater Guidelines have been detected in your site’s wastewater test report. Note that incoming water testing is also recommended in case of detection of any detox parameter.

How This Will Be Verified:

Yes

- Documentation Required:

- Wastewater test report showing the parameters tracked by the facility (Treated effluent and untreated effluent) should be available. For the ZDHC Wastewater guidance, wastewater testing should be conducted according to the frequency, test parameters, limits, sampling and testing methods. It is recommended to upload the test reports on the ZDHC Gateway – Wastewater Module.

- Documentation showing that the parameters are recorded and analyzed

- Sample procedures document

- Interview Questions to Ask:

- Are key employees aware of the wastewater discharge points in the facility?

- Is there a mechanism for employees to identify to management when wastewater is not properly being discharged?

- Are key employees who deal with the sample procedures properly trained? How often?

- Inspection – Things to Physically Look For:

- Are sumps/pits receiving wastewater in good condition and of sound integrity?

- Are surface water/storm water drains free from contamination and blockages?

- Are procedures established to manage wastewater/wastewater discharges are being followed? (e.g. management of wastewater, activities etc.)

- Please provide pictures for each treatment step of the ETP

Upload: a) Documentation of your request to offsite wastewater treatment plant for wastewater quality records; b) Off site wastewater treatment plant quality records (if provided)

It is important to be aware of any wastewater quality violations at the wastewater treatment plant in the event that your facility is contributing to environmental contamination. Although your facility does not have authority over the offsite wastewater treatment plant, please provide evidence of your request for wastewater quality results, even if quality results were not provided. This question is intended to provide you with more information in case you are able to take any action to assist the wastewater treatment plan in proper treatment and discharge to the environment.

What is the intent of the question?

The intent of this question is to create connection and accountability between the facility and the offsite wastewater treatment plant that is contracted to treat wastewater. The goal is for the facility to be as proactive as possible to confirm their wastewater is compliant and are not responsible for any violations towards environment. Regardless of the response outcome from the off-site wastewater treatment plant, the proactive effort from the facility is what is being asked in this question.

This information is useful to help understand your situation and identify risk factors and/or opportunities for improvement.

By requesting the wastewater quality test results from the offsite treatment plant, a facility ensures that treated wastewater often discharged from the offsite facility to the environment is compliant in addition to their own facility discharge compliance related to the permit between the offsite treatment plant and the facility.

Although your facility is not in control of offsite 3rd party treatment, it is important to be aware of any non-compliances and to what extent the facility may be contributing to non-compliances. In addition, if your site is contributing to the non-compliance, the question checks to ensure your facility has a plan to help resolve the issue it is causing. This was included in Level 2 rather than Level 1 as a site may not have direct control over offsite treatment or visibility to it.

Technical Guidance:

Your facility will get credit for this question as long as you can show evidence that you have reached out to the offsite wastewater treatment plant to obtain wastewater quality reports. You will not be penalized if the offsite wastewater party treatment plant refused, as long as you can provide proof of request and denial.

NOTE: If the 3rd party wastewater treatment plant posts their effluent online, the factory can answer “Yes” to this question.

Sometimes the offsite effluent treatment plant may set a standard for facility to discharge wastewater and charge facility more for any exceeding parameters. If this applies to you, please explain the situation and provide examples if relevant to capturing accurate assessment from your facility. A soft limit is not a permit limit if a surcharge is involved. They would still be compliant to their permit.

If you requested results and found that the 3rd party wastewater treatment plant is not in compliance with limits, please describe whether your facility has contributed to the non-compliance. If yes, how has your facility resolved it? If you requested test results, but did not receive them, please describe what happened.

How This Will Be Verified:

Yes

- Documentation Required:

- Recent documentation of your request to receive off-site wastewater treatment plant for wastewater quality records and/or

- Recent (within the year, but ideally more frequently) off-site wastewater treatment plant quality records (if provided)

- Interview Questions to Ask:

- Key personnel responsible for the wastewater quality explains the results of the wastewater quality test results collected from the common effluent treatment plant

- Inspection – Things to Physically Look For:

- Do the sampling results reflect the facility’s operational conditions?

Wastewater – Level 3

Questions

- Enter the percentage of wastewater treated and recycled back into your production processes

Suggested Upload: a) Records demonstrating closed-loop recycling (process water to process water) and/or b) List of water reduction achievement(s) according to the location where water is captured for recycling OR the location where recycled water is used.

Answer Yes if you have wastewater treatment in place to reuse and/or recycle your production wastewater back into production processes. The reused and/or recycled water must be used in production processes – other uses like irrigation, toilets are excluded. The actual treatment technologies may include chemical or biological such as membrane filtration or Zero Liquid Discharge.

Note on scoring:

- Reuse/Recycle 50% or more = full points

- No or unknown = zero points

What is the intent of the question?

This question is focused on incentivizing the innovative technology needed for reuse/recycling and reducing overall fresh water use footprint.

This technology nearly eliminates freshwater withdrawal for production processes.

Technical Guidance:

When the wastewater from a given process does not meet quality requirements for another process it is often simply treated and discharged. If instead a facility treats this wastewater (either chemically or biologically) to meet quality specifications for another process in the facility it would be considered reusing/recycling water. Outside of process optimization to ensure every process runs as efficiently as possible, recycling and reuse of water is the most common mechanisms for reducing freshwater use. For reuse, the wastewater from one process may still meet quality criteria for use in a second process without additional treatment. This uses the same volume of water multiple times reducing the need for freshwater in the second process.

Recycling 100% of total water use within a facility is closed-loop. This means no significant freshwater use is needed to operate the facility except natural water loss such as evaporation. Zero liquid discharge (ZLD) technologies which involves steps such as pre-treatment, evaporation and crystallization facilitate recovery and reuse of all wastewater.

A facility which is treating the waste water using Reverse Osmosis (RO) and nanofiltration technologies and reusing 80% of the waste water but the rejected water from the membrane are being sent to offsite ETPs are not considered as ZLDs as the TDS of the rejected water from the membrane technologies is considered more hazardous than the usual waste water discharged.

This water has to be reused again as process water. Other uses like irrigation and toilets are not included.

How This Will Be Verified:

- Documentation Required:

- Facility is able to prove through documented record keeping that they reuse and/or recycle process wastewater as process water. Please refer back to documentation in the Water section to evaluate whether the percentages provided here are correct based on water withdrawal and the water balance (if applicable)

- List of water reduction achievements according to:

- the location where water is captured for recycling

- the location where recycled water is used

- flow diagram of the recycling process

- Interview Questions to Ask:

- Management and responsible employees can describe/demonstrate how wastewater is reused and/or recycled as process water

- Inspection – Things to Physically Look For:

- Observation of the equipment in place for the reuse / recycling of process water

- Detailed descriptions of the equipment (function, benefits for the water consumption, age, maintenance, etc.)

- Please take a picture of the equipment

- Confirm that all reject wastewater goes through treatment (as recorded in the previous questions above) before discharge